Welcome to RITTER Engineering!

70 Years of Experience Manufacturing High Precision Measuring Instruments and Gas Meters for Research & Development

RITTER Engineering has been successful in the manufacture of measuring instruments as well as in the field of thermoplastic engineering for 70 years. In addition to innovative modular Multi-Gas Sensors and Biogas Batch Fermentation Systems, RITTER manufactures Gas Meters made out of various superior thermoplastics and high grade stainless steel, which are used world-wide in research & development laboratories as well as in industry. These meters can be used for volumetric measurement of even highly aggressive gases with laboratory precision.

Worldwide

With over 75 distributors worldwide, use a dense distribution network and get RITTER products directly at the point of contact.

Innovative

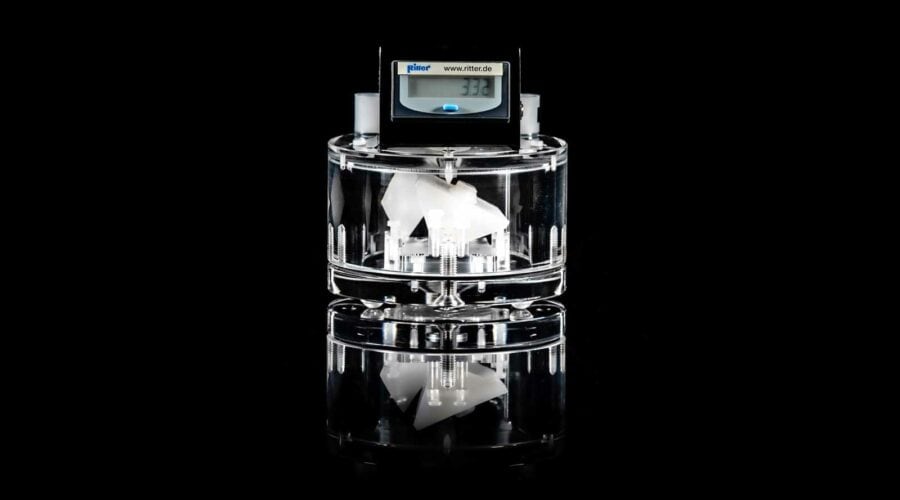

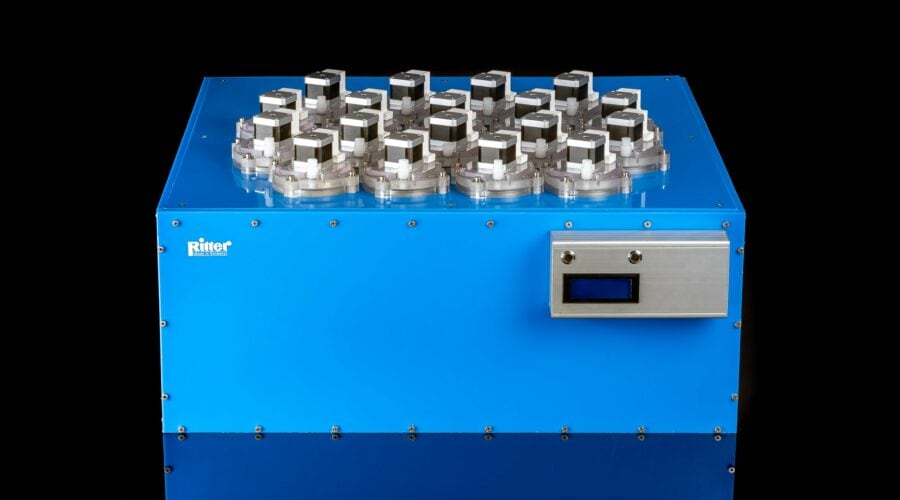

The Biogas Batch Fermentation System with automatic data logging, you save valuable time and receive at the same time up to 18 measurement results!

Maintenance Free

RITTER provides highly accurate measurement, even for highly-aggressive gases – and this for more than 25-years maintenance free!

Upcoming Events

REGATEC 2024

The 10th International Conference on Renewable Energy Gas Technology, REGATEC 2024 will take place as a hybrid event on the 15-16 May at Scandic Star Hotel in Lund, Sweden. »The conference revolved around renewable methane for G-mobility and/or grid injection, including anaerobic digestion, gasification, Power-to-gas and the synergies between these three conversion routes.« As a leading global manufacturer of high-precision…

Industries & Business Segments

Do you know RITTER?

Surely you already know a number of products from the market leader for highly accurate volumetric measurement of gas volume. But do you know who is behind it and how it came to a worldwide distribution network? And anyway: Inventing instruments for highest demands is not a finger snap! Read the whole story ...

Recent Posts

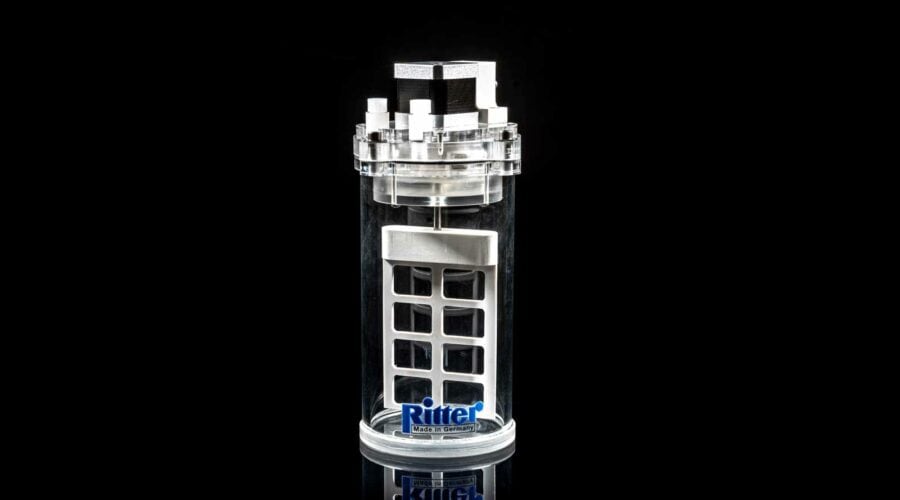

Read MoreRITTER MGC MilliGascounters Video

Read MoreRITTER MGC MilliGascounters Video Read MoreRITTER PMMA Fermentation Bottle Video

Read MoreRITTER PMMA Fermentation Bottle Video Read MoreRITTER BBFS 4.0 Video

Read MoreRITTER BBFS 4.0 Video

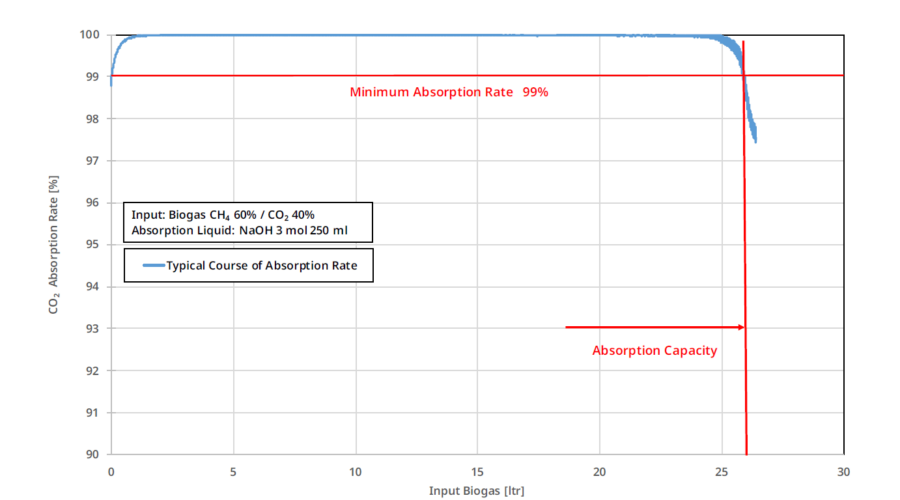

… with the RITTER CO2 Absorption Bottle Better than 99% absorption capability and you don’t even need any absorption indicator! Definition of CO2 Absorption Capacity with RITTER Absorption Bottles: The above diagram shows the definition of the CO2 absorption capacity…

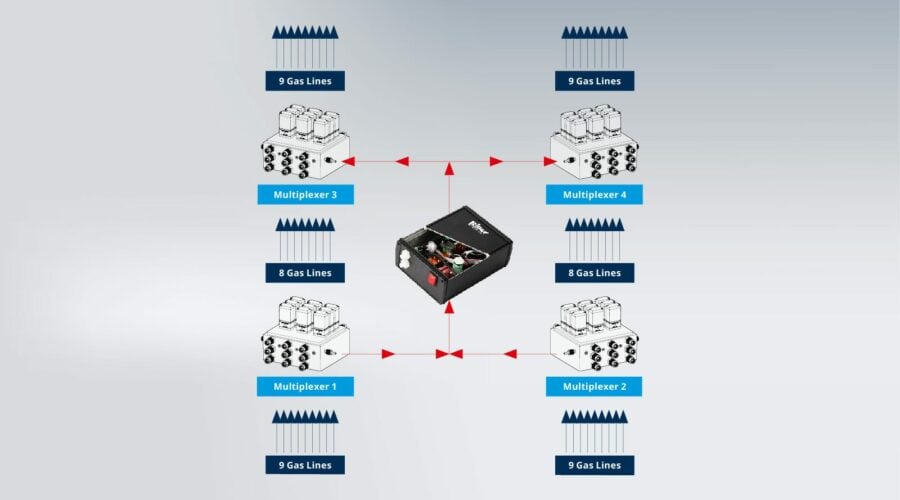

Analyse simultaneously with 3 modules up to 4 different gases in one table-top casing Modular sensor design In order to be able to adapt the measuring system as flexibly as possible to individual measuring tasks, the individual components are designed…