- 1 Specifiche generali

- 2 Svantaggi dei sensori elettrochimici (EC) rispetto ai sensori ottici RITTER »MultiGas«

- 3 Misure preventive e protettive con misurazioni di gas

- 4 Ambito di fornitura

- 5 Installazione

- 6 Sensori a infrarossi

- 7 Sensori ultravioletti

- 8 Opzioni (installato all'interno dell'involucro del sensore)

- 8.1 Sensore dell'ossigeno

- 8.2 Sensore di pressione

- 8.3 Sensore di umidità

- 8.4 RITTER »MultiGas« Modulo di regolazione del punto zero (Aria)

- 8.5 RITTER »MultiGas« Modulo di regolazione del punto zero (N2)

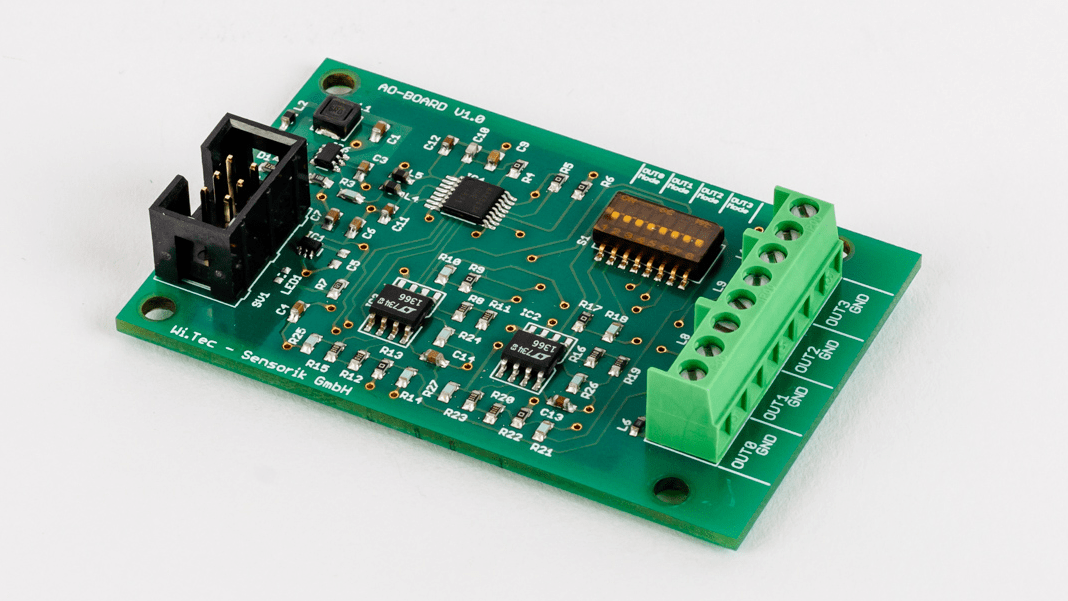

- 8.6 Uscita di tensione analogica

- 8.7 Riscaldamento e termostatazione dell'involucro del sensore

- 8.8 Filtro

- 8.9 Pompa per il campionamento del gas

Specifiche generali

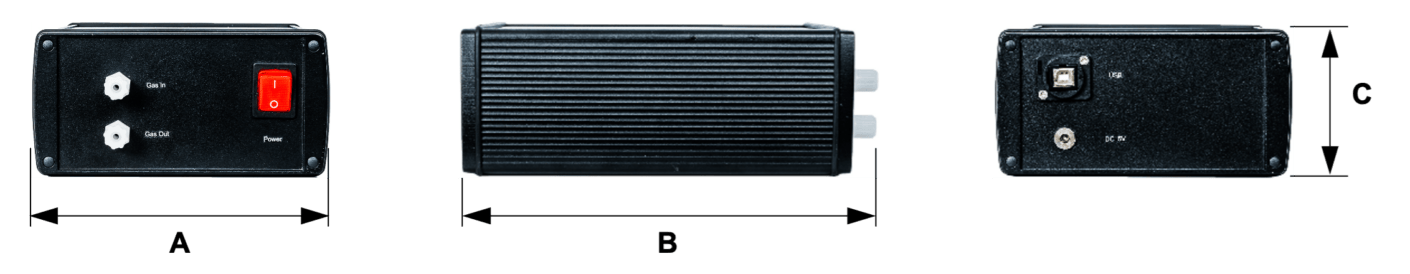

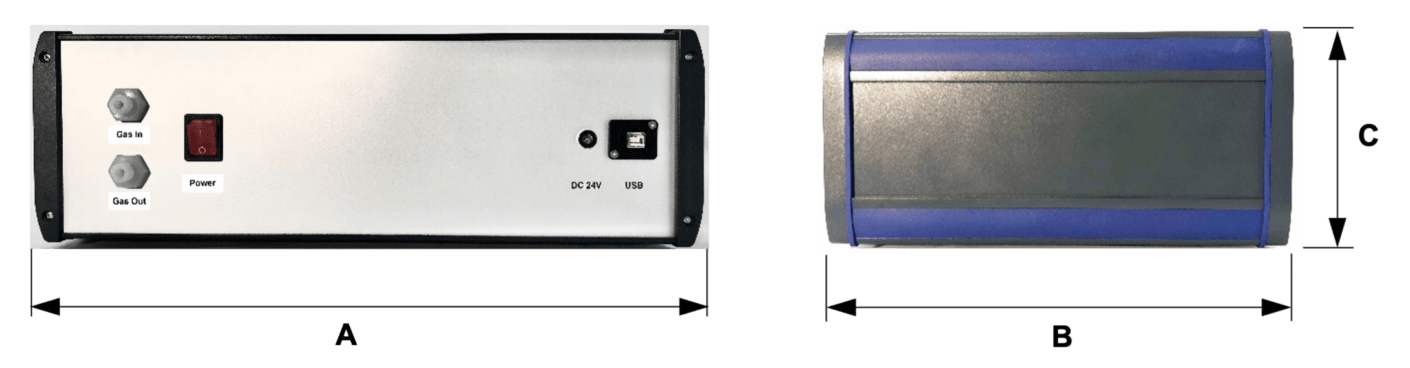

Tipi di involucro

Dimensioni & Specifiche tecniche

Tipo di involucro 1 Tipo di involucro 2 A 171 mm 444 mm B 290 mm (1) 305 mm C 86 mm 145 mm Peso, circa. (2) 2+ kg 6,5 – 8 kg Connessioni ingresso/uscita gas Raccordo a vite in PVDF per tubo Øi 4 mm, Øe 6 mm Tubo di collegamento PVC Rauclair Øi 4 mm, Øe 6 mm, 3 m Interfacce USB (standard), RS232 / CANbus / CANopen (opzioni), MODbus su richiesta Alimentazione 24 VDC, incl. alimentatore a spina

100 – 240 VAC, 50/60 Hz

(2) A seconda del tipo e del numero di moduli sensori integrati

Specifiche dell'interfaccia

USB

- Tipo: USB 2.0

- Connettore: Tipo B

- Cavo di collegamento: Tipo B /

genere A

RS232

- Tipo: RS232

- Connettore: D-sub9 femmina

- Cavo di collegamento: D-sub9 1:1 spina/spina

CANopen

- Tipo di protocollo: Modalità CANopen 2

- Baudrate: 250 kBaud

- Node ID: 0x31

- Connettore: RJ45

CANbus

- Tipo di protocollo: Modalità CANbus 1 (non standard)

- Baudrate: 250 kBaud

- ID di trasmissione: 0x208

- Ricezione ID: 0x300

- Connettore: RJ45

MODbus

- Baudrate: 250 kBaud

- Databits: 8

- Stopbit: 1

- Parity: None

- Float Definition: IEE754

- Registri disponibili:

- Read Holding Register 0x03

- Read Input Register 0x04

- Write Single Register 0x06

- Connettore: RJ45

Assegnazione dei tipi di sensore alle possibili combinazioni di sensori

Parte 1: Sensori preconfigurati incl. Tipo di involucro 1

Con raccordi per l'allacciamento al gas, interfaccia dati, alimentatore a spina - pronto per l'uso

Tipo di sensore:

RITTER MultiGas xxxArticolo

No.Gruppo di gas

IRNumero di gas rilevabili

in questo GruppoGruppo di gas

UVNumero di gas rilevabili

in questo Gruppo xxx = mono IR1 2678 1 xxx = duo IR2 2742 2 xxx = trio IR3 2743 3 xxx = mono UV1 2749 1 xxx = mono UV1

Cl2 30%2763 1 xxx = duo UV2 2766 2 xxx = duo IR1 + UV1 2797 1 1 xxx = trio IR1 + UV2 na 1 2

Parte 2: Sensori preconfigurati incl. Tipo di involucro 2

Con raccordi per l'allacciamento al gas, interfaccia dati, alimentatore a spina - pronto per l'uso

Tipo di sensore:

RITTER MultiGas xxxArticolo

No.Gruppo di gas

IRNumero di gas rilevabili

in questo GruppoGruppo di gas

UVNumero di gas rilevabili

in questo Gruppo xxx = mono UV1

H2S ≤ 5000 ppm2672 1 xxx = mono UV1

H2S ≤ 1%2855 1 xxx = UVRAS 2812 1 xxx = duo IR1

+ H2S ≤ 5000 ppm2959 1 1 xxx = duo IR1

+ (H2S ≤ 1% / NO)2960 1 1

Parte 3: Moduli sensore combinabili singolarmente

Composizione secondo le specifiche del cliente, consegna comprensiva di alloggiamento di dimensioni adeguate in base al numero e al tipo di moduli - pronto per l'uso

Tipo di sensore:

RITTER MultiGas xxxArticolo

No.Gruppo di gas

IRNumero di gas rilevabili

in questo GruppoGruppo di gas

UVNumero di gas rilevabili

in questo Gruppo xxx = Mod IR1 2813 1 xxx = Mod IR2 2814 2 xxx = Mod IR3 2815 3 xxx = Mod UV1 2830 1 xxx = Mod UV1

Cl2 30%na 1 xxx = Mod UV1

H2S ≤ 5000 ppm2841 1 xxx = Mod UV1

H2S ≤ 1%2856 1 xxx = Mod UV2 2831 2 xxx = Mod UVRAS 2917 3

Parte 4: Involucri per moduli sensore

Assemblati secondo le specifiche del cliente

Tipo di involucro:

RITTER MultiGasArticolo

No.Tipo di involucro Adatto per xxx = Cas-2 (1) 2817 Tipo di involucro 2 Moduli multipli fino a 444 x 305 x 145 mm xxx = Cas-3 (1) 2818 Tipo di involucro 3 Moduli multipli fino a 444 x 305 x 189 mm

Parte 5: Opzioni integrate

Tipo di opzione:

RITTER MultiGasArticolo

No.Descrizione Campo di misura RMS-O2 (2) (3) 2795 Sensore dell'ossigeno 0 ‐ 25% RMS-O2 (2) (3) 2767 Sensore dell'ossigeno 0 – 100% RMS-O2-resist (3) 2824 Sensore dell'ossigeno

H2S resistente0,5 – 35% RMS-P (2) (3) 2771 Sensore di pressione 800 – 1200 mbar ass.

Risoluzione <1 mbar RMS-P-resist (3) 2825 Sensore di pressione

H2S resistente0,2 – 3,5 bar ass.

Risoluzione 2 mbar RMS-H (2) (3) 2773 Sensore di umidità 0 – 100% RH RMS-A/O 2648 Uscita di tensione analogica

0-2 V / 0-5 V / 0-10 V4 porte di uscita analogiche per 4 concentrazioni di gas separate

16 bit RMS‐CasHeat 2954 Involucro termostatato Riscaldamento e termostatazione dell'involucro del sensore a 45 °C

(3) Disponibile come supplemento al solo sensore IR o UV

Parte 6: Accessori / Opzioni

Tipo di opzione:

RITTER MultiGas xxxArticolo

No.Descrizione Campo di misura xxx = Cal-ZP-N2 2805 Gas di calibrazione N2 Per la calibrazione a punto zero di tutti i gas xxx = Flow-V 2806 Mini valvola di flusso Controllo della portata della bombola di gas di calibrazione

Manometro incluso xxx = Cal-CG-Cat1 2948 Calibrazione con gas vettore speciale (Ar, H2, He)

per i gas di categoria 1Gas di categoria 1:

xxx = Cal-CG-Cat2 2949 Calibrazione con gas vettore speciale (Ar, H2, He)

per i gas di categoria 2Gas di categoria 2:

xxx = Cal-ReCal-Cat1 2950 Ricalibrazione per gas di categoria 1 Gas di categoria 1:

xxx = Cal-ReCal-Cat2 2951 Ricalibrazione per gas di categoria 2 Gas di categoria 2:

Infrared module NDIR Modulo ultravioletto NDUV

Calibrazioni

A seconda del numero di gas da analizzare, è necessario selezionare un gas di calibrazione adeguato. Inoltre, anche il tipo di gas influisce sul gas di calibrazione ottimale. A causa del numero quasi infinito di combinazioni possibili, l'elenco seguente deve essere inteso solo come una prima panoramica.

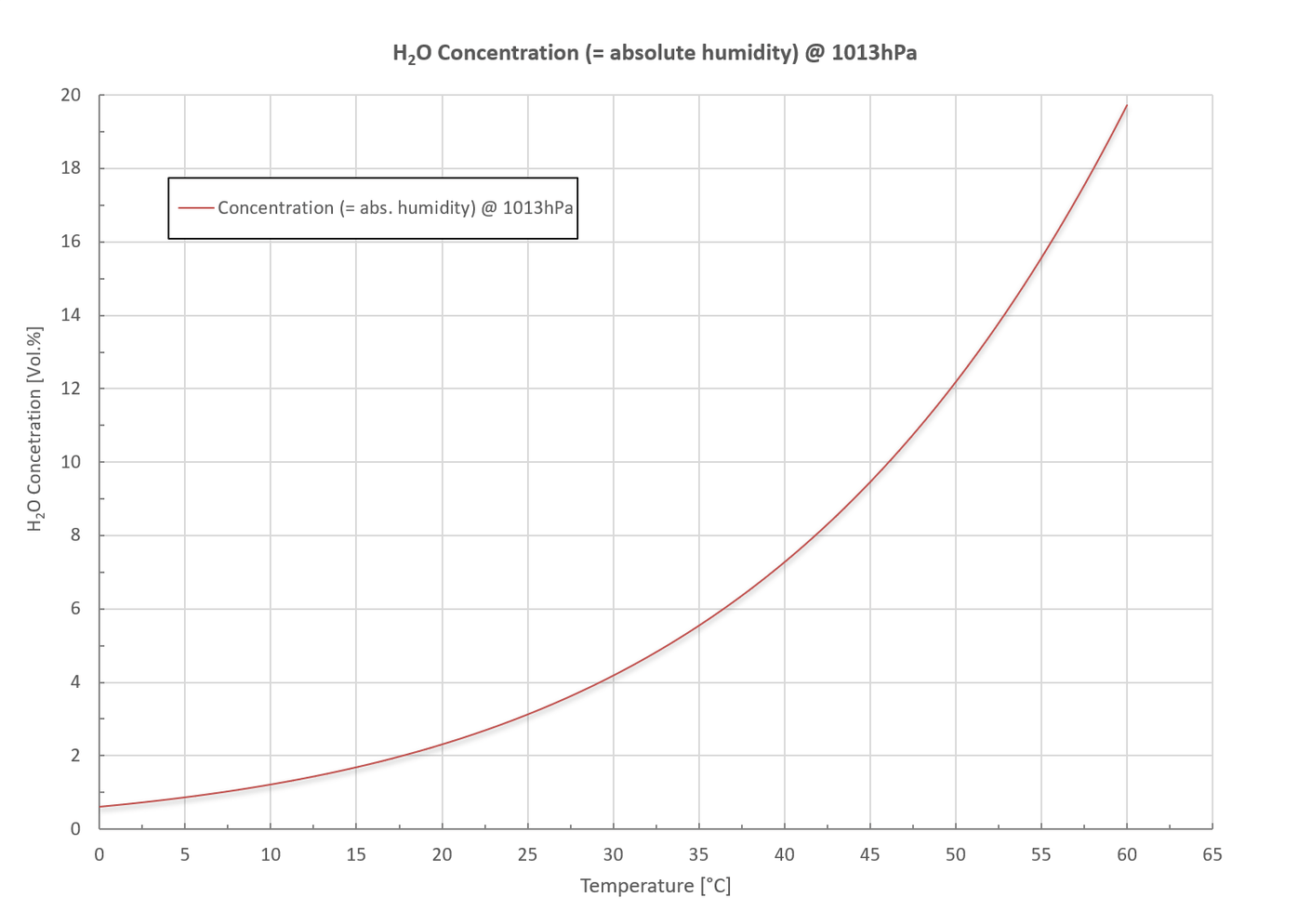

Misura dei gas umidi

Quando si misurano gas umidi, è essenziale evitare la condensazione del vapore acqueo all'interno del sensore. Il diagramma seguente mostra la concentrazione massima di vapore acqueo ( = umidità assoluta) in volume % in funzione della temperatura alla pressione standard di 1013 mbar.

Il diagramma mostra:

La condensa può essere evitata con le seguenti misure:

Con il sensore di umidità opzionale è possibile misurare l'umidità relativa nell'intervallo di misura da 0 a 100% rH. Inoltre, è possibile misurare anche l'umidità assoluta in g/m³. Entrambi i valori sono visualizzati nel software in dotazione.

Svantaggi dei sensori elettrochimici (EC) rispetto ai sensori ottici RITTER »MultiGas«

Misure preventive e protettive con misurazioni di gas

Importante: Specificare le opzioni desiderate al momento dell'ordine

a) Attacco per tubo supplementare per il lavaggio dell'involucro

Le linee del gas all'interno dell'involucro e la cuvetta di misurazione sono a tenuta di gas per mezzo di O-ring e altre connessioni a tenuta di gas. Tuttavia, come per tutte le connessioni, non si può escludere un tasso di perdita, anche se minimo. Con un tubo di collegamento aggiuntivo per il lavaggio dell'involucro, è possibile evitare l'accumulo del gas di misura all'interno dell'involucro.

Nel caso di gas tossici o aggressivi, è possibile collegare una linea di aspirazione attraverso questo tubo di connessione, che crea una sottopressione all'interno dell'alloggiamento impedendo così la fuoriuscita del gas dall'involucro.

In caso di gas infiammabili (metano, idrogeno, ecc.), è possibile collegare una linea di pressione o di aspirazione attraverso questo raccordo tubolare, creando una sovrapressione o una sottopressione all'interno dell'involucro e impedendo così l'accumulo di una miscela di gas infiammabili.

Notare che: L'H2S può essere percepito come un odore sgradevole anche nell'intervallo di ppb. Anche con una guarnizione O-ring, possono verificarsi microperdite, che possono essere eliminate con un lavaggio dell'alloggiamento.

b) Involucro riscaldato e termostatato

È necessario evitare la condensazione del gas di misura all'interno del sensore. Questo può essere ottenuto generalmente con una trappola per la condensa o un raffreddatore di gas. Consultare anche la sezione »Misurazione dei gas umidi«. In alternativa, l'interno dell'involucro del sensore può essere riscaldato e termostatato a 45 °C (standard). Il riscaldamento non solo evita la formazione di condensa all'interno del sensore, ma garantisce anche risultati di misura costanti. Vedere »Riscaldamento e termostatazione dell'involucro del sensore«.

c) Filtro antiparticolato

Assicurarsi che, utilizzando un filtro adeguato, non vengano trasportate particelle nel sensore. Queste potrebbero ostruire le piccole aperture dei raccordi interni. Si consiglia di utilizzare filtri da 5 micron o più piccoli.

Ambito di fornitura

| Numero di articoli | Articolo |

|---|---|

| 1 | Cartella di documenti comprendente: Certificato di calibrazione / Schede tecniche / Manuale del software |

| 1 | Sensore in custodia da tavolo |

| 1 | Alimentatore a spina Ingresso: 100 – 240 V-AC, 50/60 Hz, 0,4 A Uscita: 24 V-DC, 0,5 A, 12 W o 36 W (H2S / Sensore UVRAS) |

| 1 | Software di acquisizione dati (su scheda di memoria USB) |

| 1 | Cavo di collegamento: Sensore → PC Standard: USB V2.0 A/B, 1 m Opzione: RS232, 3m |

| 3m | Tubo in Viton Øi 4mm / Øe 6mm |

Installazione

- Disimballare con cura tutti gli articoli.

- Installare il software di acquisizione dati secondo il »RITTER MultiGas Software Manual«.

Non avviare il software in questo momento. - Posizionamento del sensore:

- Se il sensore viene utilizzato in combinazione con un MilliGascounter RITTER, il sensore deve essere posizionato (in direzione del flusso) davanti al MilliGascounter se questo viene riempito di soluzione di HCl. In caso contrario, il sensore potrebbe essere danneggiato dai vapori di HCl che fuoriescono dal MilliGascounter.

- Posizionare il sensore vicino alla sorgente di gas.

Notare che: Un tubo di collegamento tra la sorgente di gas e i sensori il più corto possibile consente di ridurre lo spazio morto creato dal tubo. A sua volta, uno spazio morto ridotto consente un tempo di risposta rapido del sensore.

- Collegare l'alimentatore alla presa »DC 24 V« sul lato posteriore del sensore e alla rete elettrica.

- Collegare il cavo di acquisizione dati alla rispettiva presa sul lato posteriore del sensore e al computer:

- Cavo USB alla presa »USB«

- Cavo RS232 alla presa »RS 232« (option)

- Collegare la sorgente di gas alla porta di ingresso del gas del sensore utilizzando il tubo in dotazione come segue:

- Rimuovere i tappi a vite e i tappi di gomma rossa del blocco per il trasporto dall'ingresso e dall'uscita del gas.

- Far scorrere il tappo a vite sull'estremità del tubo di ingresso del gas con la filettatura del tappo a vite rivolta verso l'estremità del tubo.

- Spingere il tubo sul cono al centro della porta di ingresso del gas.

- Far scorrere il tappo a vite sulla porta di ingresso del gas e avvitarlo a mano.

- Se applicabile: Collegare la porta di uscita del gas del sensore ad altri componenti, quali sacche di campionamento del gas, tubi di scarico, ecc. Il collegamento del tubo alla porta di uscita del gas avviene nello stesso modo descritto sopra.

- Inserire l'interruttore di alimentazione sul lato anteriore dell'involucro del sensore.

- Avviare il software e aprire la/e porta/e COM del/i modulo/i sensore/i collegato/i secondo il manuale del software.

Il sensore RITTER »MultiGas« è ora pronto per l'uso.

Sensori a infrarossi

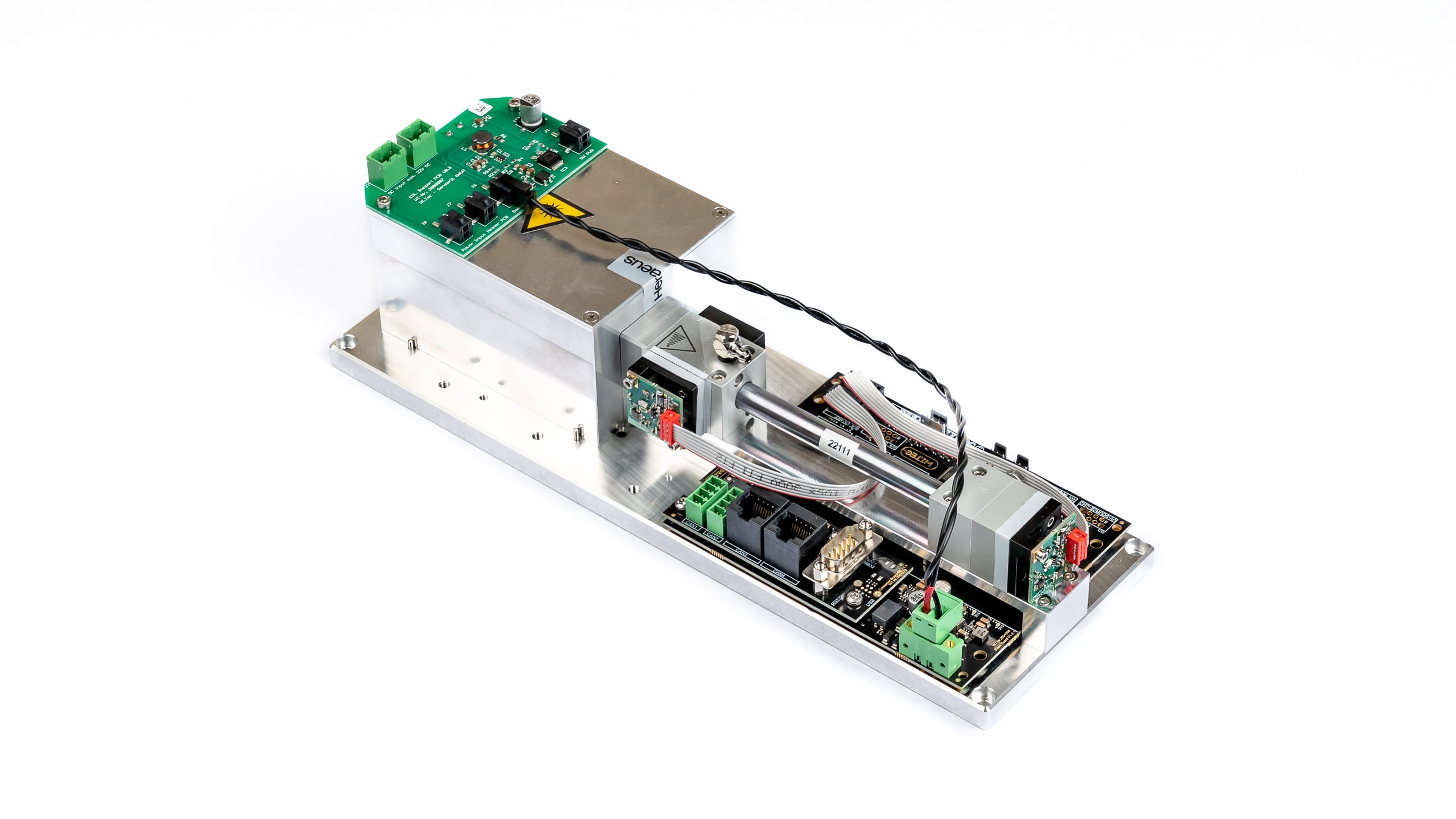

MultiGas Modulo Infrarosso NDIR

Descrizione

L'analisi dei gas basata sulla tecnica NDIR è un metodo consolidato per determinare le concentrazioni di gas in miscele complesse. I sensori RITTER »MultiGas« utilizzano nuovi componenti ottici per ottenere risultati di analisi ottimali: Fino a 3 filtri ottici analizzano il gas che passa attraverso il sensore come un unico flusso di gas. I sensori opzionali di ossigeno, pressione e umidità sono in linea con lo stesso flusso di gas.

I singoli moduli interni sono sigillati mediante connessioni O-ring.

Per ottenere un adattamento ottimale al campo di misura richiesto, le lunghezze delle celle di misura modulari (= cuvette) possono variare da 5 mm (grande campo di misura in percentuale) a 250 mm (piccolo campo di misura in ppm).

Le cuvette di lunghezza ≥ 20 mm sono rivestite con uno strato d'oro resistente per migliorare le proprietà di riflessione per il rilevamento di bassi livelli di concentrazione e offrire una protezione aggiuntiva contro i gas leggermente corrosivi. Anche le cuvette utilizzate con gas aggressivi sono rivestite d'oro.

Le altre parti meccaniche interne sono realizzate in alluminio, a scelta in acciaio inox.

Per le applicazioni a risposta rapida, il sistema di misura fornisce un risultato stabile entro t90 ≈ 3 secondi.

L'intera unità può essere smontata per facilitare la manutenzione e l'assistenza.

Applicazioni

Specifiche tecniche

Caratteristiche Generali

| Tecnologia di misurazione: | Innovativo sensore NDIR (sensore a infrarossi non dispersivo) |

| Gas rilevabili: | CO2 CO N2O CnHm CH4 CF4 SF6 H2O |

| Numero di gas rilevabili simultaneamente: | max. 3 per unità sensore |

| Campi di misura: | Vedi Tabella dei campi di misura |

| Campo di portata: | 5 ~ 300 ltr/h Per portate più elevate il sensore può funzionare in bypass |

| Pressione massima di ingresso del gas: | 300 mbar |

| Perdita di pressione (senza sensori opzionali aggiuntivi): | 10 @ 100 / 35 @ 200 / 70 @ 300 (mbar @ ltr/h) |

| Compensazione della temperatura: | Si |

| Software di acquisizione dati: | Si |

| Durata della sorgente di radiazioni IR: | > 40 000 h |

| Ciotola di misurazione: | Alluminio, con campi di misura ≤1% placcato oro all'interno |

| Sigillatura della cuvetta: | O-ring in Viton |

| Involucro: | Cassa da tavolo di alta qualità, in alluminio |

| Dimensioni (W x H x L): | 171 x 86 x 290 mm |

| Peso: | circa 2 kg |

| Connessioni del gas: | Raccordo a vite in PVDF per tubo Øi 4 mm, Øe 6 mm |

Dati di misurazione

| Errore di linearità: | < ± 1% F.S. |

| Ripetibilità: | ± 0,5% F.S. |

| Stabilità a lungo termine zero: | < ± 2% F.S. / settimana |

| Durata della stabilità a lungo termine: | < ± 2% F.S. / mese |

| Influenza della temperatura sul punto zero: | < 1% F.S. / 10K |

| Influenza della temperatura sull'intervallo: | < 2% F.S. / 10K |

| Sensibilità trasversale: | < 2% F.S. |

| Influenza della pressione: | < 1.5% / 10hPa dal valore misurato |

| Tempo di riscaldamento: | 2 min |

| Tempo di risposta (t90): | ≈ 3 sec |

| Frequenza di campionamento tramite software: | ≤ 10 Hz |

| Limite di rilevamento: | Vedi Tabella dei limiti di rilevamento |

| Risoluzione: | 0,5 x limite di rilevamento |

| Vapore acqueo: | Nessuna influenza sulle misure di CO2 e CH4. |

Caratteristiche elettriche

| Alimentazione: | 24 VDC inclusa la spina di alimentazione 100 ~ 240 VAC 50/60 Hz: 24 VDC |

| Consumo medio di energia: | < 1W |

| Interfaccia: | USB (standard), RS232 / CANbus / CANopen (opzioni) incl. cavo di trasmissione dati 1 m |

| Uscita di tensione analogica (option): | 0 – 2 V / 0 – 5 V / 0 – 10 V |

Parametri del gas

| Temperatura di esercizio: | +15 ~ +45 °C |

| Temperatura di stoccaggio: | –20 ~ +60 °C |

| Pressione di esercizio: | 800 ~ 1200 hPa (mbar) |

| Umidità ambientale: | 0 ~ 95% umidità relativa È necessario evitare la formazione di condensa all'interno del sensore! |

* Analisi di CnHm: La calibrazione dei sensori per CnHm sarà effettuata con il propano. Vengono misurati anche gli idrocarburi aromatici, ma con una ponderazione diversa. Ciò significa che la sensibilità del sensore è significativamente inferiore con questi gas rispetto agli altri idrocarburi.

Elenco dei campi di misura standard *1 ( e limiti di rilevamento *2 )

| Campi di misura standard con i rispettivi limiti di rilevamento ( % di F.S. *3 ) | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 Vol.% | 50 Vol.% | 30 Vol.% | 20 Vol.% | 10 Vol.% | 5 Vol.% | 1 Vol.% | 5.000 ppm | 2.000 ppm | 1.000 ppm | 500 ppm | 300 ppm | 100 ppm | 50 ppm | 10 ppm | 1 ppm | |

| CO2 | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,3%) | (< 0,3%) | ||||

| CO | (< 0,2%) | (< 0,2%) | (< 0,2%) | (< 0,2%) | (< 0,2%) | (< 0,2%) | (< 0,2%) | (< 0,3%) | (< 0,5%) | (< 0,5%) | ||||||

| N2O | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,3%) | ||||||||

| CnHm*4 | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,2%) | (< 0,2%) | (< 0,2%) | (< 0,2%) | (< 0,5%) | (< 0,5%) | |||||||

| CH4 | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,3%) | (< 0,5%) | |||||||

| CF4 | (< 0,2%) | (< 0,2%) | (< 0,2%) | (< 0,02%) | (< 0,05%) | |||||||||||

| SF6 | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,2%) | (< 0,5%) | (< 0,3%) | (< 0,3%) | |||||||||

| H2O | ||||||||||||||||

Infrared module NDIR Modulo ultravioletto NDUV

Definizione di limite di rilevamento

Il limite di rilevamento è il più piccolo valore di misura che può essere ottenuto con una specifica incertezza. Questa incertezza comprende la risoluzione, il rumore e la stabilità del sensore di gas per un gas specifico e un intervallo di misurazione specifico. Per valutare il valore del limite di rilevamento, vengono effettuate diverse misure singole alle stesse condizioni di misurazione. Con i risultati delle singole misure ottenuti si calcola la deviazione standard »Sigma« (σ). I valori indicati nella tabella corrispondono alla quantità tripla di Sigma.

Ricalibrazioni

Per i sensori IR si consigliano i seguenti intervalli di ricalibrazione:

Sensori ultravioletti

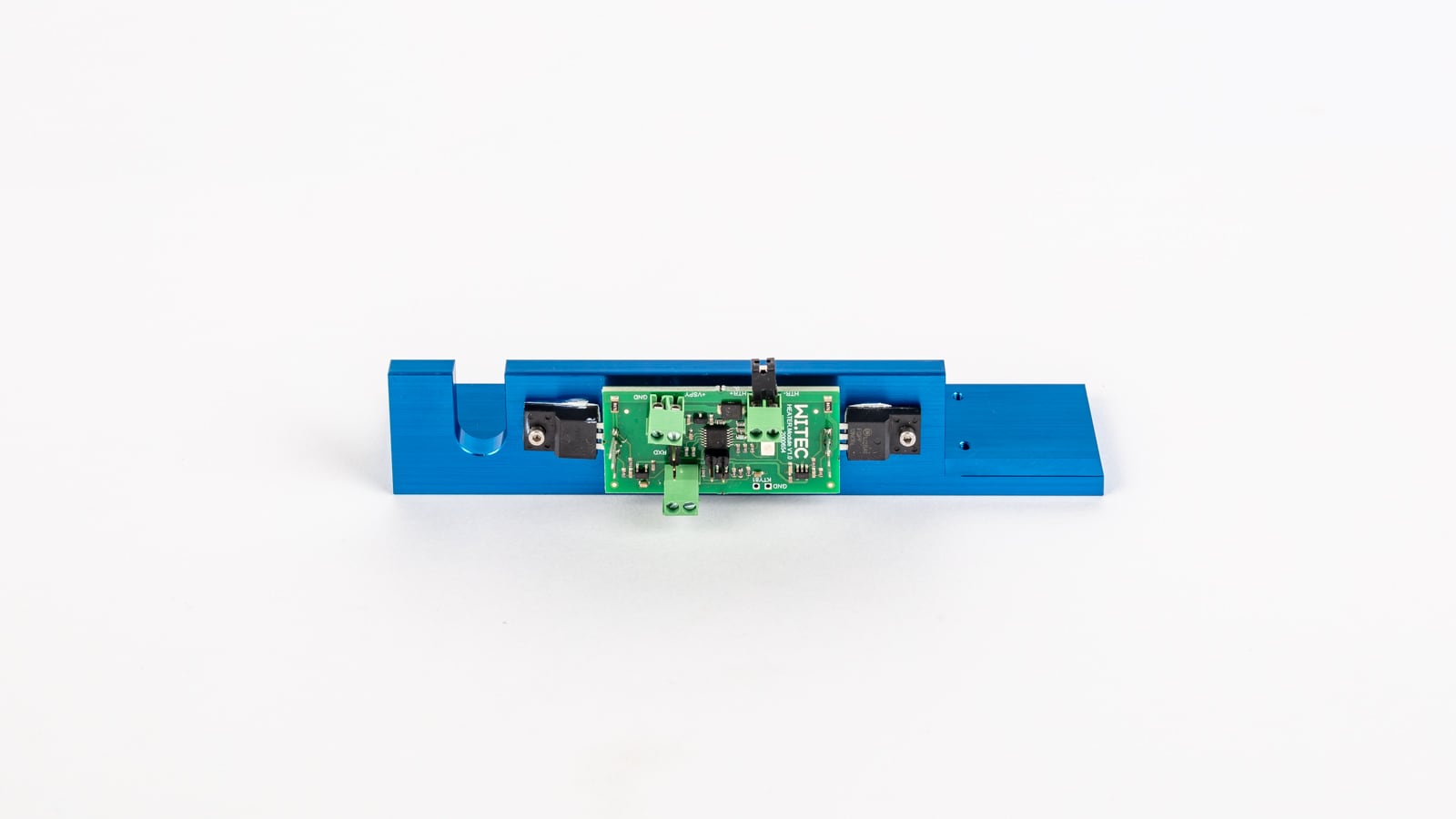

Il sensore UV »MultiGas« di RITTER è il primo modulo di analisi dei gas al mondo basato su LED UV miniaturizzati. La stabilità e la durata di questi LED UV consentono un'analisi dei gas di alta precisione fino alla gamma dei ppm. Utilizzando due LED UV è possibile rilevare contemporaneamente due gas. Inoltre, con questo approccio è possibile realizzare campi di misura da ppm a Vol.-%. Nella gamma spettrale da 200 a 500 nm, gli ossidi di azoto (NO + NO2), gli idrocarburi aromatici, l'idrogeno solforato, l'ozono, l'anidride solforosa e il cloro possono essere rilevati in modo affidabile con questa nuova piattaforma di sensori. L'intera unità può essere smontata per facilitare la manutenzione e l'assistenza. I singoli moduli interni sono sigillati mediante connessioni O-ring. Per ottenere un adattamento ottimale al campo di misura richiesto, le lunghezze delle celle di misura modulari (= cuvette) possono variare da 5 mm (grande campo di misura in percentuale) a 250 mm (piccolo campo di misura in ppm). Le cuvette di lunghezza ≥ 20 mm sono rivestite con uno strato d'oro resistente per migliorare le proprietà di riflessione per la rilevazione di bassi livelli di concentrazione. Anche le cuvette utilizzate con gas aggressivi sono rivestite in oro. Le parti meccaniche interne sono realizzate in alluminio, in opzione in acciaio inox. Per le applicazioni a risposta rapida, il sistema di misura fornisce un risultato stabile entro t90 ≈ 1-2 secondi. Infrared module NDIR Modulo ultravioletto NDUV Definizione di limite di rilevamento Il limite di rilevamento è il più piccolo valore di misura che può essere ottenuto con una specifica incertezza. Questa incertezza comprende la risoluzione, il rumore e la stabilità del sensore di gas per un gas specifico e un intervallo di misurazione specifico. Per valutare il valore del limite di rilevamento, vengono effettuate diverse misure singole alle stesse condizioni di misurazione. Con i risultati delle singole misure ottenuti si calcola la deviazione standard »Sigma« (σ). I valori indicati nella tabella corrispondono alla quantità tripla di Sigma. Per i sensori UV si raccomandano i seguenti intervalli di ricalibrazione: Per la rilevazione di NO viene utilizzata una EDL (lampada a scarica elettrodica). Nell'EDL, N2 e O2 vengono convertiti in NO e producono una radiazione UV selettiva. Grazie a questa radiazione, è possibile misurare l'NO senza sensibilità incrociata. Questo metodo è chiamato spettroscopia di assorbimento a risonanza UV (UVRAS). La combinazione delle tecnologie UVRAS e NDUV consente l'analisi simultanea di NO, NO2 e SO2 in un intervallo di ppm inferiore, particolarmente importante nell'analisi dei fumi (monitoraggio continuo delle emissioni, CEM). Infrared module NDIR Modulo ultravioletto NDUV Definizione di limite di rilevamento Il limite di rilevamento è il più piccolo valore di misura che può essere ottenuto con una specifica incertezza. Questa incertezza comprende la risoluzione, il rumore e la stabilità del sensore di gas per un gas specifico e un intervallo di misurazione specifico. Per valutare il valore del limite di rilevamento, vengono effettuate diverse misure singole alle stesse condizioni di misurazione. Con i risultati delle singole misure ottenuti si calcola la deviazione standard »Sigma« (σ). I valori indicati nella tabella corrispondono alla quantità tripla di Sigma. Per i sensori UV si raccomandano i seguenti intervalli di ricalibrazione: Il sensore H2S funziona secondo il principio dell'assorbimento UV non dispersivo (NDUV). La lunghezza d'onda utilizzata è nell'intervallo dei nanometri inferiori, il che consente di effettuare misure senza interferenze con il vapore acqueo e gli idrocarburi. Ciò rende il sensore ideale per le misurazioni del biogas, poiché i gas di accompagnamento come NH3, CO2, CH4 e H2O non influiscono sull'accuratezza delle misure. A differenza dei sensori NDUV fotometrici, la vita dei sensori elettrochimici per la misurazione di H2S è limitata. Si noti che i dati sulla durata di tali sensori sono forniti per l'aria e non per la misurazione di H2S. Per concentrazioni di H2S > 200 ppm la durata è ridotta, per concentrazioni > 1000 ppm è critica. Mentre le prestazioni di misura degli UV-LED sono costanti, i sensori EC stanno diventando »sordi«. Infrared module NDIR Modulo ultravioletto NDUV Definizione di limite di rilevamento Il limite di rilevamento è il più piccolo valore di misura che può essere ottenuto con una specifica incertezza. Questa incertezza comprende la risoluzione, il rumore e la stabilità del sensore di gas per un gas specifico e un intervallo di misurazione specifico. Per valutare il valore del limite di rilevamento, vengono effettuate diverse misure singole alle stesse condizioni di misurazione. Con i risultati delle singole misure ottenuti si calcola la deviazione standard »Sigma« (σ). I valori indicati nella tabella corrispondono alla quantità tripla di Sigma. Per i sensori UV si raccomandano i seguenti intervalli di ricalibrazione: Il sensore di ossigeno è disponibile solo come modulo aggiuntivo a un sensore RITTER »MultiGas« NDIR o NDUV. La concentrazione di ossigeno misurata viene visualizzata nel software in dotazione. Il sensore è integrato nell'involucro dei sensori RITTER »MultiGas«. Sono disponibili le seguenti versioni: * relativo a Pa = 1013 hPa, Ta = 25 °C, RH = 50%, flusso = 2,5 l/min Una variazione del gas e/o della pressione atmosferica causa una variazione del numero di molecole per volume e quindi una variazione della densità del gas. Questa variazione di densità ha a sua volta un'influenza significativa sul risultato della misurazione della concentrazione da parte del sensore. Misurando la pressione del gas all'interno della cella del campione (cuvetta), il valore della misurazione della concentrazione viene compensato/corretto. Il sensore di pressione consente di aumentare l'accuratezza della misurazione dell'analisi dei gas di un fattore pari al 15: Il sensore di pressione è sempre integrato nei sensori NDIR »MultiGas« di RITTER come microsensore. È disponibile come opzione per i sensori NDUV ed è integrato nell'involucro del sensore. Il valore di pressione misurato viene visualizzato nel software in dotazione. Per i gas non aggressivi: Per H2S e gas acidi simili: Il sensore di umidità è disponibile solo come modulo aggiuntivo a un sensore RITTER »MultiGas« NDIR o NDUV. Il sensore è integrato nell'involucro dei sensori RITTER »MultiGas«. I valori di umidità misurati (assoluti e relativi) vengono visualizzati nel software in dotazione. Il modulo di uscita analogica di tensione consente di emettere simultaneamente fino a 4 valori diversi su 4 canali separati: Per il collegamento a un dispositivo di acquisizione dati analogico, la porta di uscita della tensione analogica fornisce alternativamente i seguenti livelli di tensione: L'intervallo di tensione è preimpostato in base all'ordine e non può essere modificato dall'utente. Tenere presente le assegnazioni delle misure di concentrazione di gas ai rispettivi canali. Queste assegnazioni sono indicate nel protocollo di calibrazione dell'unità sensore. Assegnazione dei contatti ai canali delle misure di concentrazione di gas sulla presa e sul connettore dell'uscita analogica di tensione: Segnali di uscita analogici dei sensori di ossigeno e umidità: Solo uno di questi due segnali può essere trasmesso alternativamente. Il cavo di collegamento viene fornito con fili aperti da collegare al dispositivo di acquisizione dati analogico dell'utente. I colori dei fili sono elencati nella tabella precedente. Per evitare la condensazione di gas umidi all'interno del sensore, il sensore e l'involucro del sensore possono essere riscaldati e termostatati. Per impostazione predefinita, il regolatore di temperatura è preimpostato a 45 °C; su richiesta, sono possibili temperature inferiori. L'elemento riscaldante e il regolatore di temperatura sono montati sul supporto della cuvetta di misurazione. Il filtro per particelle di gas viene fornito come accessorio per quelle applicazioni in cui l'utente non esegue una filtrazione aggiuntiva del gas. È progettato come filtro in linea che può essere facilmente inserito nel tubo del gas davanti a tutti i sensori RITTER »MultiGas«. Notare che: È essenziale che le particelle non entrino nel sensore, poiché ostruirebbero le piccole aperture all'interno del sensore. Ogni sensore viene fornito con un filtro per ogni linea del gas. Il filtro viene inserito nel tubo di alimentazione mediante un raccordo a vite. I filtri aggiuntivi possono essere ordinati presso il vostro partner nazionale di distribuzione RITTER. MultiGas Modulo Ultravioletto NDUV

Descrizione

Applicazioni

Specifiche tecniche

Caratteristiche Generali

Tecnologia di misurazione: Sensore NDUV innovativo

(sensore ultravioletto non dispersivo)Gas rilevabili: Numero di gas rilevabili simultaneamente: max. 2 Campi di misura: Vedi Tabella dei campi di misura Campo di portata: 5 ~ 300 ltr/h

Per portate più elevate il sensore può funzionare in bypassPressione massima di ingresso del gas: 300 mbar Perdita di pressione (senza sensori opzionali aggiuntivi): 10 @ 100 / 35 @ 200 / 70 @ 300 (mbar @ ltr/h) Compensazione della temperatura: Si Software di acquisizione dati: Si Durata della sorgente di radiazioni UV: > 8 000 h Ciotola di misurazione: Acciaio inossidabile con rivestimento interno in silicone Sigillatura della cuvetta: O-ring in Viton Tubo interno: FKM / Viton (gomma fluorurata) Involucro: Cassa da tavolo di alta qualità, in alluminio Dimensioni (L x H x L): 464 x 189 x 305 mm Peso: circa 6,5+ kg Connessioni del gas: Raccordo a vite in PVDF per tubo Øi 4 mm, Øe 6 mm Dati di misurazione

Errore di linearità: < ± 1% F.S. Ripetibilità: ± 0,5% F.S. Stabilità a lungo termine zero: < ± 1% F.S. / 24 h Durata della stabilità a lungo termine: < ± 1% F.S. / month Influenza della temperatura sul punto zero: < 1% F.S. / 10K Influenza della temperatura sull'intervallo: < 2% F.S. / 10K Sensibilità trasversale: < 2% F.S. Influenza della pressione: < 1,5% / 10 hPa dal valore misurato Tempo di riscaldamento: 1 min (iniziale), < 60 min per le specifiche complete Tempo di risposta (t90): 1,5 – 15 sec Frequenza di campionamento tramite software: ≤ 10 Hz Limite di rilevamento: Vedi Tabella dei campi di misura Risoluzione: 0,5 x limite di rilevamento Caratteristiche elettriche

Alimentazione: 24 VDC inclusa la spina di alimentazione 100 ~ 240 VAC

50/60 Hz: 24 VDC Corrente di alimentazione (picco) < 0,4 A Consumo medio di energia < 7,5 W Interfaccia: USB (standard)

RS232 / CANbus / CANopen (opzioni)

incl. cavo di trasmissione dati 1 m Uscita di tensione analogica (option): 0-2 V / 0-5 V / 0-10 V Parametri del gas

Temperatura di esercizio: +25 ~ +45 °C Temperatura di stoccaggio: –20 ~ +60 °C Pressione di esercizio: 800 ~ 1200 hPa (mbar) Umidità ambientale: 0 ~ 95% umidità relativa

È necessario evitare la formazione di condensa all'interno del sensore!Elenco dei campi di misura standard *1 ( e limiti di rilevamento *2 )

Campi di misura standard con i rispettivi limiti di rilevamento ( % di F.S. *3 ) 100

Vol.%50

Vol.%30

Vol.%20

Vol.%10

Vol.%5

Vol.%1

Vol.%5.000

ppm2.000

ppm1.000

ppm500

ppm300

ppm100

ppm50

ppm10

ppm1

ppm O3

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,2%)

(< 0,5%)

(< 0,5%)

(< 0,5%) CL2

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,2%)

(< 0,5%) SO2

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,5%)

(< 0,5%)

(< 0,5%) H2S

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,2%)

(< 0,5%) NO2

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,2%)

(< 0,2%)

(< 0,5%)

(< 0,5%)

(< 0,5%) NO

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,2%)

(< 0,2%) Ricalibrazioni

MultiGas Modulo Ultravioletto NDUV / UVRAS

Descrizione

Applicazioni

Specifiche tecniche

Caratteristiche Generali

Tecnologia di misurazione: Spettroscopia di assorbimento a risonanza UV (UVRAS) Gas rilevabili: Numero di gas rilevabili simultaneamente: max. 3 per unità sensore Campi di misura: Vedi Tabella dei campi di misura Campo di portata: 5 ~ 300 ltr/h

Per portate più elevate il sensore può funzionare in bypassPressione massima di ingresso del gas: 300 mbar Perdita di pressione (senza sensori opzionali aggiuntivi): 10 @ 100 / 35 @ 200 / 70 @ 300 (mbar @ ltr/h) Custodia aggiuntiva riscaldata e termostatata all'interno dell'involucro del sensore: Si Compensazione della temperatura: Si Software di acquisizione dati: Si Durata delle sorgenti di radiazioni UV: LED > 20 000 h (NO2, SO2)

EDL > 8 000 h (NO)Ciotola di misurazione: Acciaio inossidabile con rivestimento interno in silicone Sigillatura della cuvetta: O-ring in Viton Tubo interno: FKM / Viton (gomma fluorurata) Involucro: Cassa da tavolo di alta qualità di tipo 2, alluminio Dimensioni (L x H x L): 464 x 189 x 305 mm Peso: circa 6,5+ kg Connessioni del gas: Raccordo a vite in PVDF per tubo Øi 4 mm, Øe 6 mm Dati di misurazione

Errore di linearità: < ± 1% F.S. Ripetibilità: ± 0,5 % F.S. Stabilità a lungo termine zero: < 3 ppm / 24 h Durata della stabilità a lungo termine: < ± 1 % F.S. / mese Influenza della temperatura sul punto zero: < 1 % F.S. / 10 K Influenza della temperatura sull'intervallo: < 2 % F.S. / 10 K Sensibilità trasversale: 500 ppm NO2 < 2 ppm

100 ppm SO2 < 2 ppm

100 ppm N2O < 10 ppm

20 °C D.P. H2O < 10 ppm

Influenza della pressione: < 1,5% / 10 hPa dal valore misurato Tempo di riscaldamento: 1 min (iniziale), < 60 min per le specifiche complete Tempo di risposta (t90): 1,5 ~ 15 sec Frequenza di campionamento tramite software: ≤ 10 Hz Limite di rilevamento: Vedi Tabella dei campi di misura Risoluzione: 0,5 x limite di rilevamento Caratteristiche elettriche

Alimentazione: 24 VDC inclusa la spina di alimentazione 100 ~ 240 VAC

50/60 Hz: 24 VDCCorrente di alimentazione (picco): 1,5 A Corrente di spunto: 0,2 ~ 0,7 A Consumo di energia: 36 W Interfaccia: USB (standard)

RS232 / CANbus / CANopen (opzioni)

incl. cavo di trasmissione dati 1 mUscita di tensione analogica (option): 0-2 V / 0-5 V / 0-10 V Parametri del gas

Temperatura di esercizio: +5 ~ +40 °C Temperatura di stoccaggio: –20 ~ +60 °C Pressione di esercizio: 800 ~ 1200 hPa (mbar) Umidità ambientale: 0 ~ 95% umidità relativa

È necessario evitare la formazione di condensa all'interno del sensore!Elenco dei campi di misura standard *1 ( e limiti di rilevamento *2 )

Campi di misura standard con i rispettivi limiti di rilevamento ( % di F.S. *3 ) 100

Vol.%50

Vol.%30

Vol.%20

Vol.%10

Vol.%5

Vol.%1

Vol.%5.000

ppm2.000

ppm1.000

ppm500

ppm300

ppm100

ppm50

ppm10

ppm1

ppm SO2

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,5%)

(< 0,5%)

(< 0,5%) NO2

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,2%)

(< 0,2%)

(< 0,5%)

(< 0,5%)

(< 0,5%) NO

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,2%)

(< 0,2%) Ricalibrazioni

MultiGas Modulo Ultravioletto NDUV / H2S

Descrizione

Applicazioni

Specifiche tecniche

Caratteristiche Generali

Tecnologia di misurazione: Sensore NDUV innovativo

(sensore ultravioletto non dispersivo)

Doppio raggioGas rilevabili: Numero di gas rilevabili simultaneamente: max. 2 Campi di misura: Vedi Tabella dei campi di misura Campo di portata: 5 ~ 300 ltr/h

Per portate più elevate il sensore può funzionare in bypassPressione massima di ingresso del gas: 300 mbar Perdita di pressione (senza sensori opzionali aggiuntivi): 10 @ 100 / 35 @ 200 / 70 @ 300 (mbar @ ltr/h) Compensazione della temperatura: Si Software di acquisizione dati: Si Durata della sorgente di radiazioni UV: > 8 000 h Ciotola di misurazione: Acciaio inossidabile con rivestimento interno in silicone Sigillatura della cuvetta: O-ring in Viton Tubo interno: FKM / Viton (gomma fluorurata) Involucro: Cassa da tavolo di alta qualità, in alluminio Dimensioni (L x H x L): 300 x 100 x 81 mm Peso: circa 1670 g Connessioni del gas: Raccordo a vite in PVDF per tubo Øi 4 mm, Øe 6 mm Dati di misurazione

Errore di linearità: < ± 1% F.S. Ripetibilità: ± 0,5% F.S. Stabilità a lungo termine zero: < ± 1% F.S. / 24 h Durata della stabilità a lungo termine: < ± 1% F.S. / mese Influenza della temperatura sul punto zero: < 1% F.S. / 10K Influenza della temperatura sull'intervallo: < 2% F.S. / 10K Sensibilità trasversale: < 2% F.S. Influenza della pressione: < 1,5% / 10 hPa of reading Tempo di riscaldamento: 1 min (iniziale), < 15 min per le specifiche complete Tempo di risposta (t90): 1,5 – 15 sec Frequenza di campionamento tramite software: ≤ 10 Hz Limite di rilevamento: Vedi Tabella dei campi di misura Risoluzione: 0,5 x limite di rilevamento Caratteristiche elettriche

Alimentazione: 24 VDC inclusa la spina di alimentazione 100 ~ 240 VAC

50/60 Hz: 24 VDC Corrente di alimentazione (picco): < 0,4 A Consumo medio di energia: < 7,5 W Interfaccia: USB (standard)

RS232 / CANbus / CANopen (opzioni)

incl. cavo di trasmissione dati 1 m Uscita di tensione analogica (option): 0-2 V / 0-5 V / 0-10 V Parametri del gas

Temperatura di esercizio: +5 ~ +45 °C Temperatura di stoccaggio: –20 ~ +60 °C Pressione di esercizio: 800 ~ 1200 hPa (mbar) Umidità ambientale: 0 ~ 95% umidità relativa

È necessario evitare la formazione di condensa all'interno del sensore!Elenco dei campi di misura standard *1 ( e limiti di rilevamento *2 )

Campi di misura standard con i rispettivi limiti di rilevamento ( % di F.S. *3 ) 100

Vol.%50

Vol.%30

Vol.%20

Vol.%10

Vol.%5

Vol.%1

Vol.%5.000

ppm2.000

ppm1.000

ppm500

ppm300

ppm100

ppm50

ppm10

ppm1

ppm SO2

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,5%)

(< 0,5%)

(< 0,5%) H2S

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,1%)

(< 0,2%)

(< 0,5%) Ricalibrazioni

Opzioni (installato all'interno dell'involucro del sensore)

Sensore dell'ossigeno

Panoramica

Specifiche tecniche

Caratteristiche Generali

Versione Versione standard Versione resistente a H2S Campo di misura 0 – 25 Vol.% O2 0 – 100 Vol.% O2 0,5 – 35 Vol.% O2 Applicazione Biogas, Analizzatore di gas di scarico per autoveicoli Industriale, completamente resistente a CO2 Industriale, completamente resistente a CO2,

mostra un'elevata resistenza ai gas acidiMateriali a medio contatto ABS, FKM, PPS, PTFE, acciaio inossidabile ABS, PVC, PPS, PTFE, acciaio inossidabile ABS, PVC, PPS, PTFE,

acciaio inossidabileVita operativa prevista 1.000.000 Vol.% O2 h ~ 1.200.000 Vol.% O2 h ~ 1.200.000 Vol.% O2 h Durata del sensore 4 anni ad aria ambiente,

a seconda dell'applicazione6 anni ad aria ambiente,

a seconda dell'applicazione6 anni ad aria ambiente Dimensioni

(Altezza x Larghezza x Lunghezza)65,4 mm × 31,7 mm × 56,6 mm Peso 70 g Connettore per tubo 4/6 mm tubo Dati di misurazione *

Versione Versione standard Versione resistente a H2S Campo di misura 0 – 25 Vol.% O2 0 – 100 Vol.% O2 0,5 – 35 Vol.% O2 Risoluzione 0,1 Vol.% 0,1 Vol.% 0,1 Vol.% Tempo di risposta (t90) < 3,5 s < 10 s < 5 s Deriva ** < 1% al mese < 1% al mese < 3% al mese Errore di linearità 0 – 2 Vol.% O2: ± 0,1 ass.

2,1 – 100 Vol.% O2: ± 0,05 rel.0 – 2 Vol.% O2: ± 0,1 ass.

2,1 – 35 Vol.% O2: ± 0,05 rel.Ripetibilità *** ± 1 Vol.% O2 ± 1 Vol.% O2 Influenza dell'umidità –0,03 % rel. Valore misurato dell'O2 /

% RH–0,03 % rel. Valore misurato dell'O2 /

% RH–0,03 % rel. Valore misurato dell'O2 /

% RHInterferenze CO2: fino a 20 Vol.%

CO: fino a 2000 ppm

NOx: fino a 5000 ppm

HC: fino a 5000 ppm

N2O: fino a 500 ppm< 20 ppm O2 risposta a:

100 Vol.% CO

100 Vol.% CO2

100 Vol.% C3H8

3000 ppm NO in N2

1000 ppm C6H6 in N2

500 ppm SO2 in N2

< 100 ppm O2 risposta a:

3000 ppm C2H6O

3000 ppm C4H10S

< 200 ppm O2 risposta a:

3000 ppm C2H6S2

< 400 ppm O2 risposta a:

100 Vol.% H2

< 500 ppm O2 risposta a:

2000 ppm H2S in N2< 20 ppm O2 risposta a:

100 Vol.% CO

100 Vol.% CO2

100 Vol.% C3H8

1000 ppm C6H6 in N2

2000 ppm H2S in N2

< 20000 ppm O2 risposta a:

3000 ppm NO in N2

1000 ppm H2 in N2

500 ppm SO2 in N2

** media su 12 mesi

*** @ 100 Vol.% O2 applicato per 5 minutiParametri del gas

Versione Versione standard Versione resistente a H2S Campo di misura 0 – 25 Vol.% O2 0 – 100 Vol.% O2 0,5 – 35 Vol.% O2 Temperatura di esercizio 0 – 40 °C

intermittente 40 – 50 °C0 – 45 °C 0 – 50 °C Temperatura di stoccaggio -20 – 40 °C

5 – 25 °C raccomandato

40 – 50 °C max. 1 settimana5 – 30 °C raccomandato

-20 – 50 °C massimoPressione dell'aria 650 – 1250 hPa (mbar) 700 – 1250 hPa (mbar) 600 – 1250 hPa (mbar) Umidità ambientale 0 – 95% umidità relativa (non condensante) Sensore di pressione

Panoramica

Specifiche tecniche

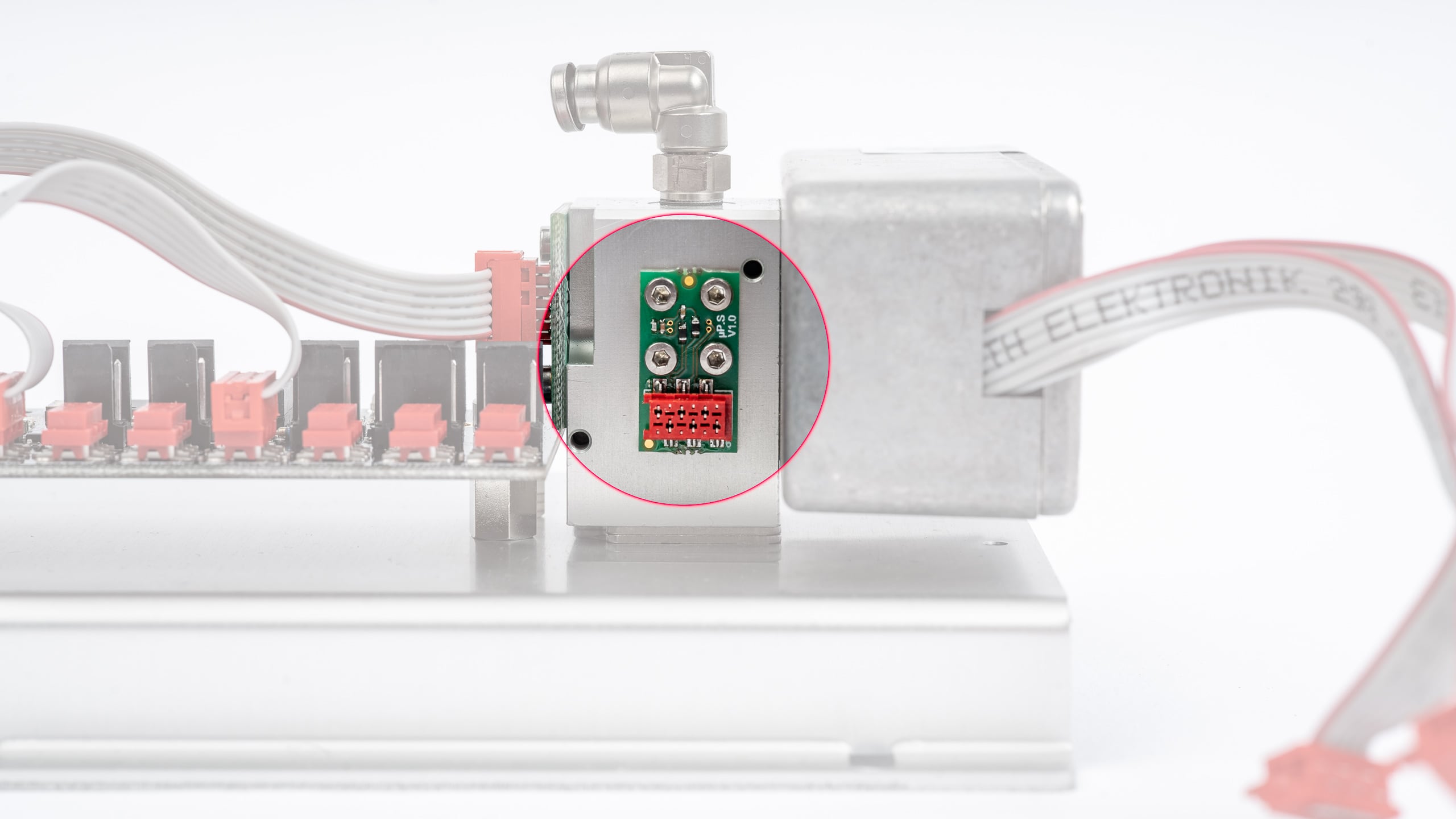

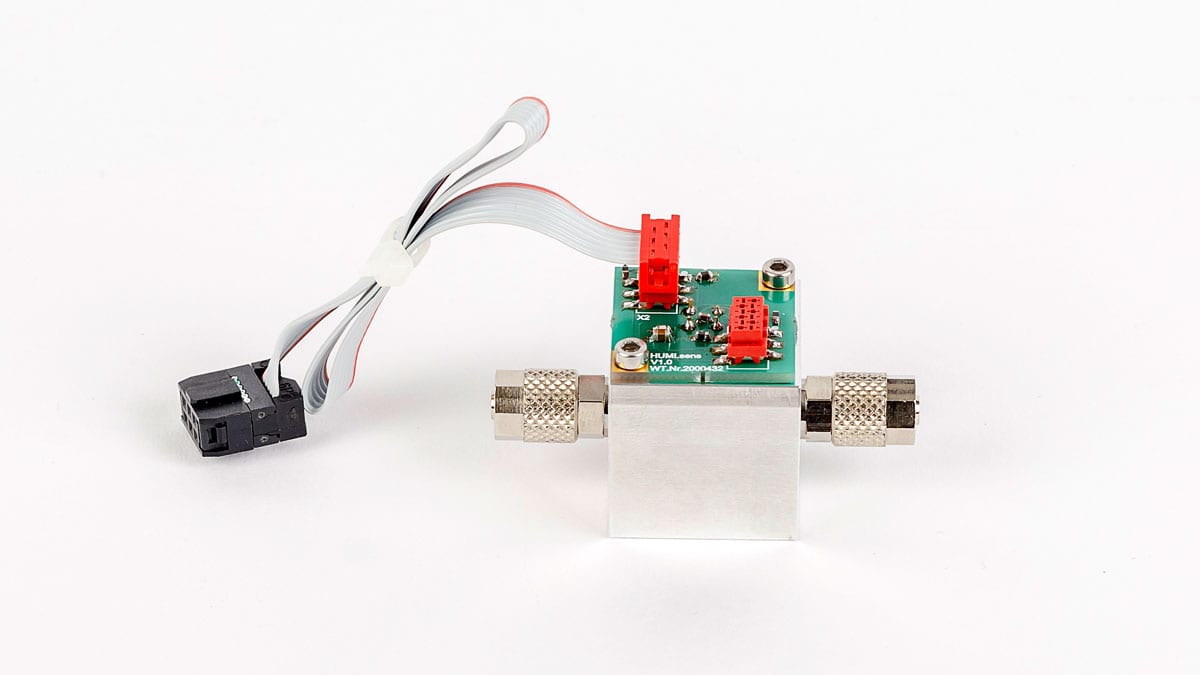

Sensore di umidità

Panoramica

Specifiche tecniche

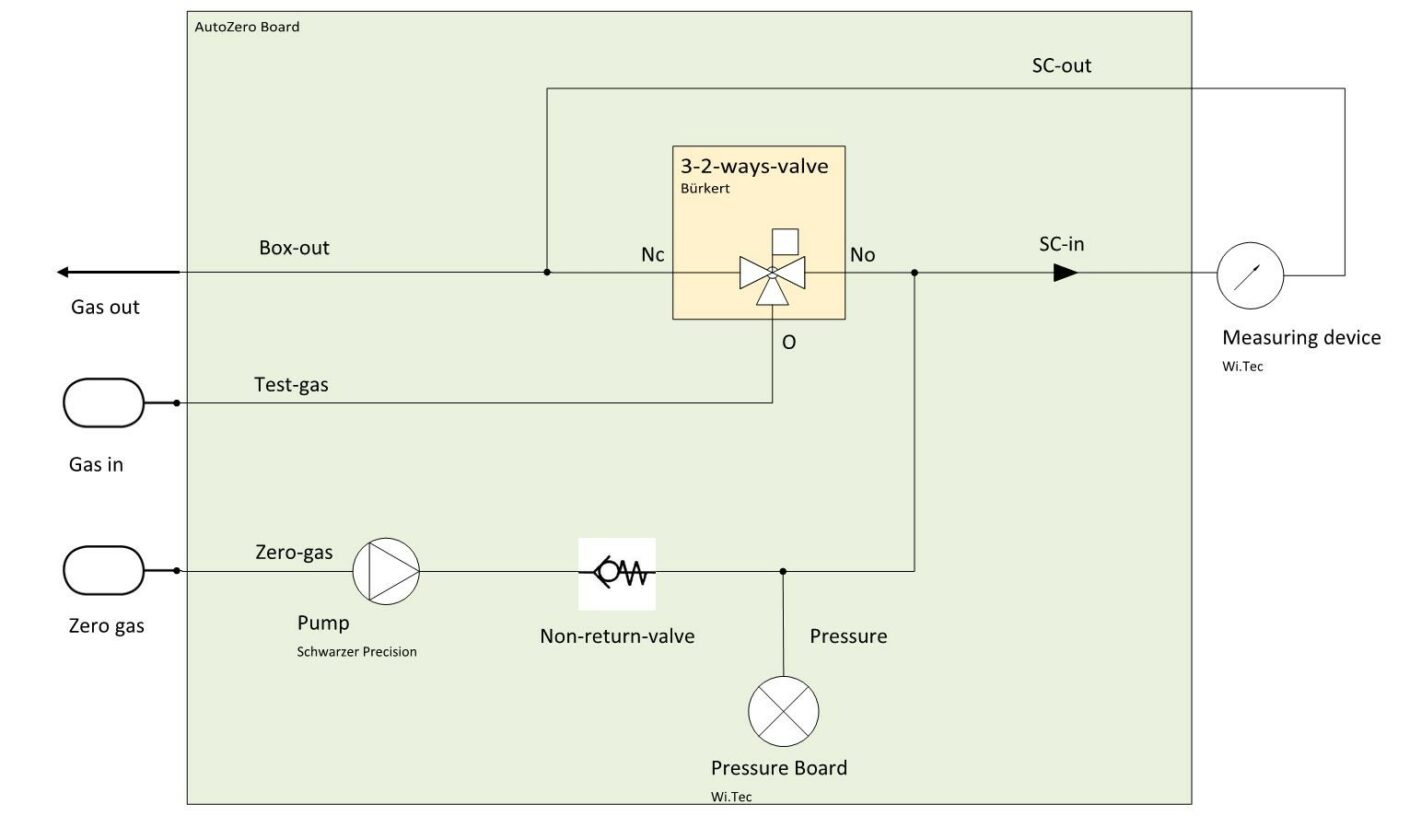

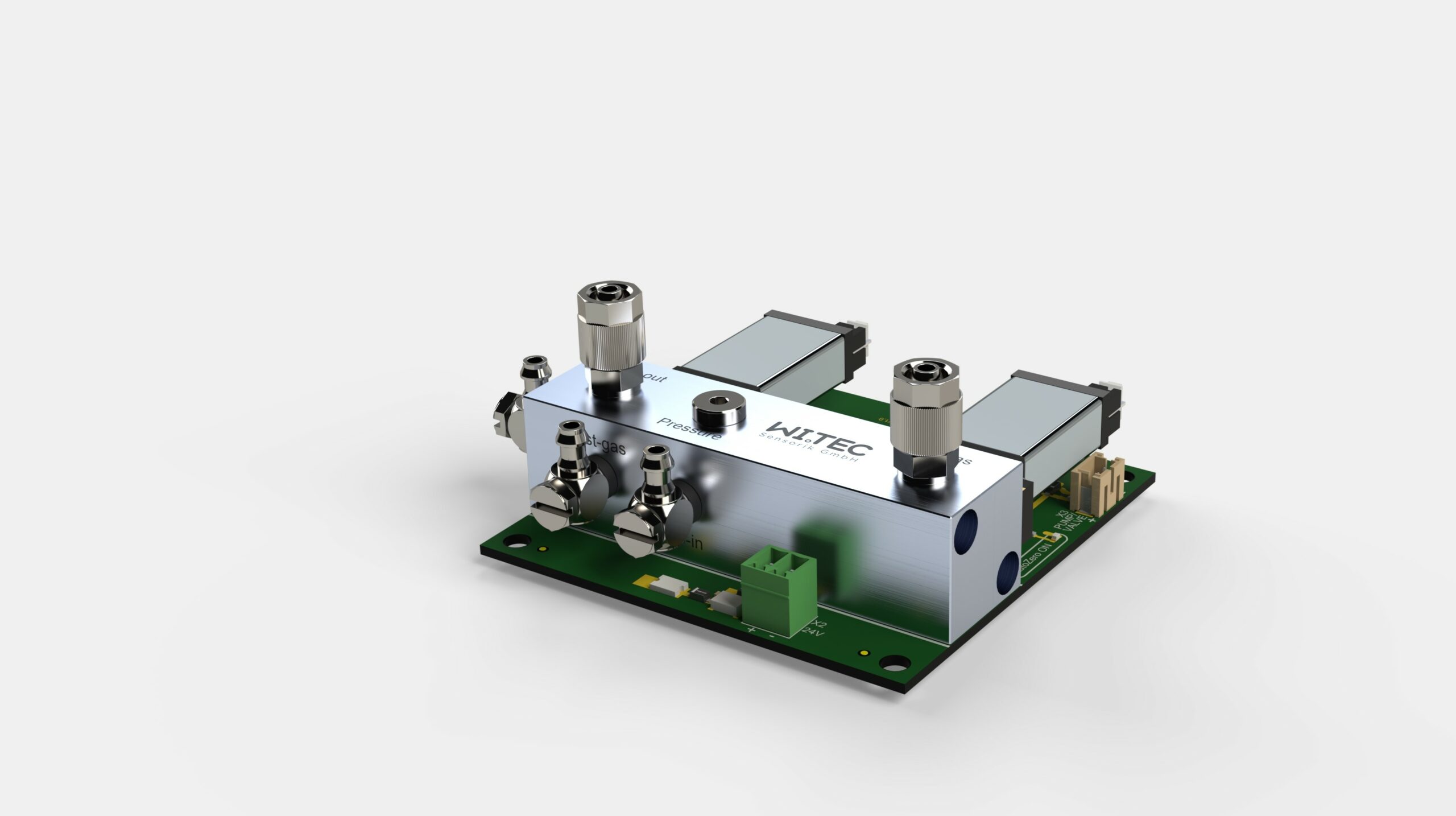

RITTER »MultiGas« Modulo di regolazione del punto zero (Aria)

Panoramica

Funzionalità

Specifiche tecniche

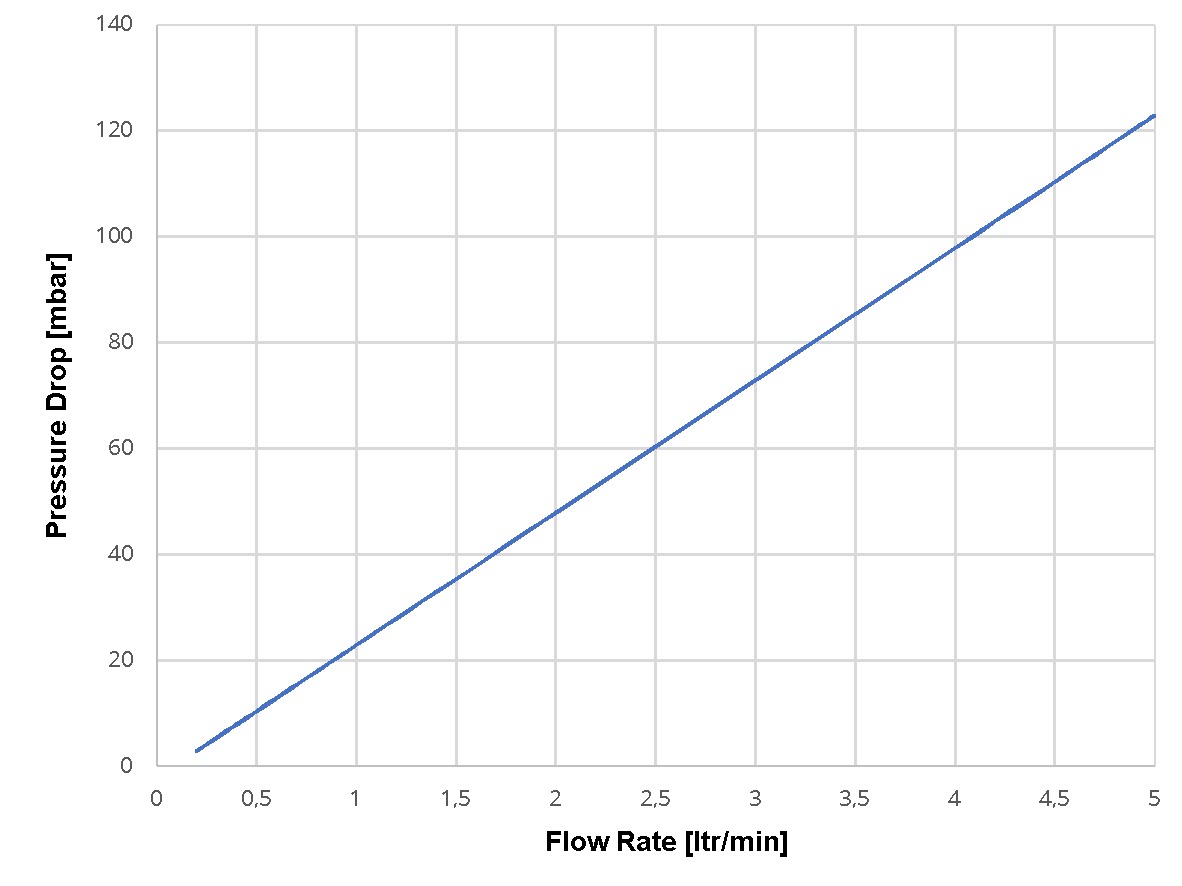

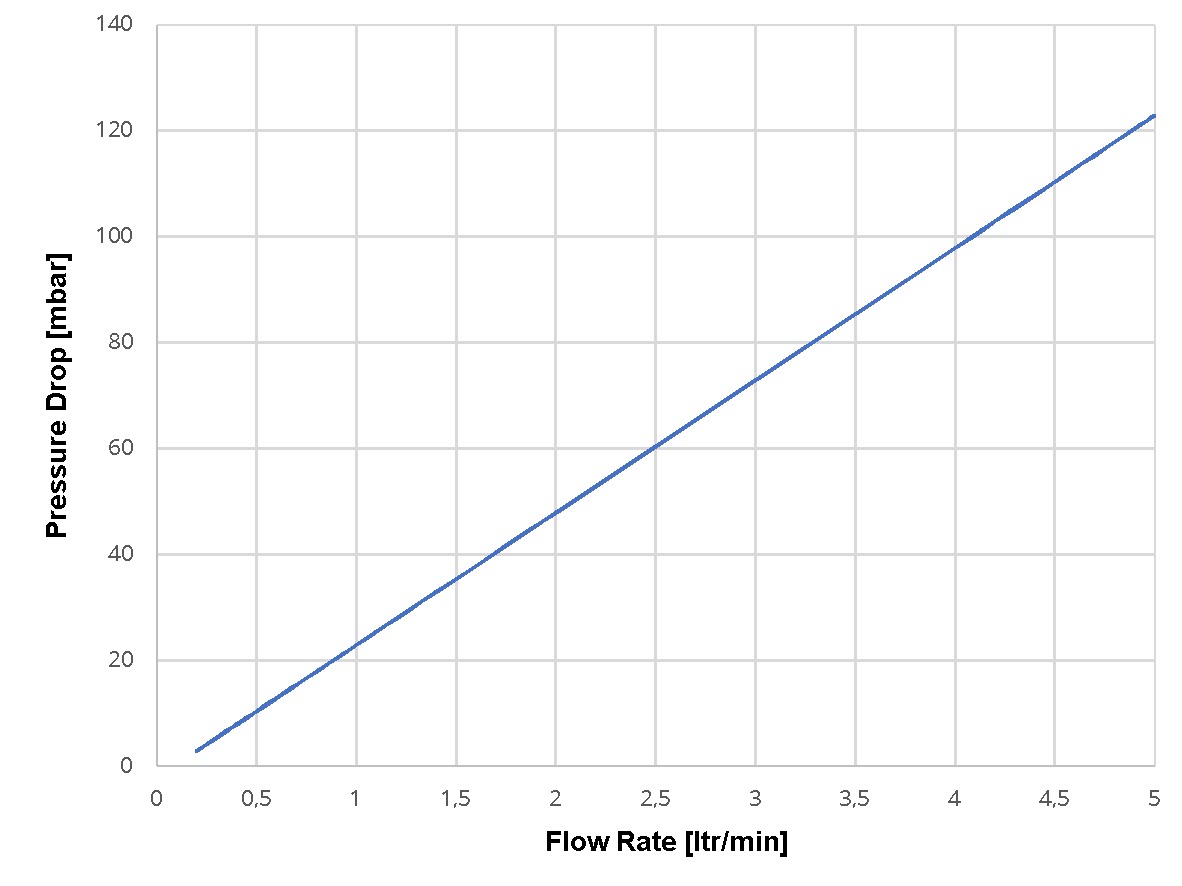

Caduta di pressione

Schema del circuito

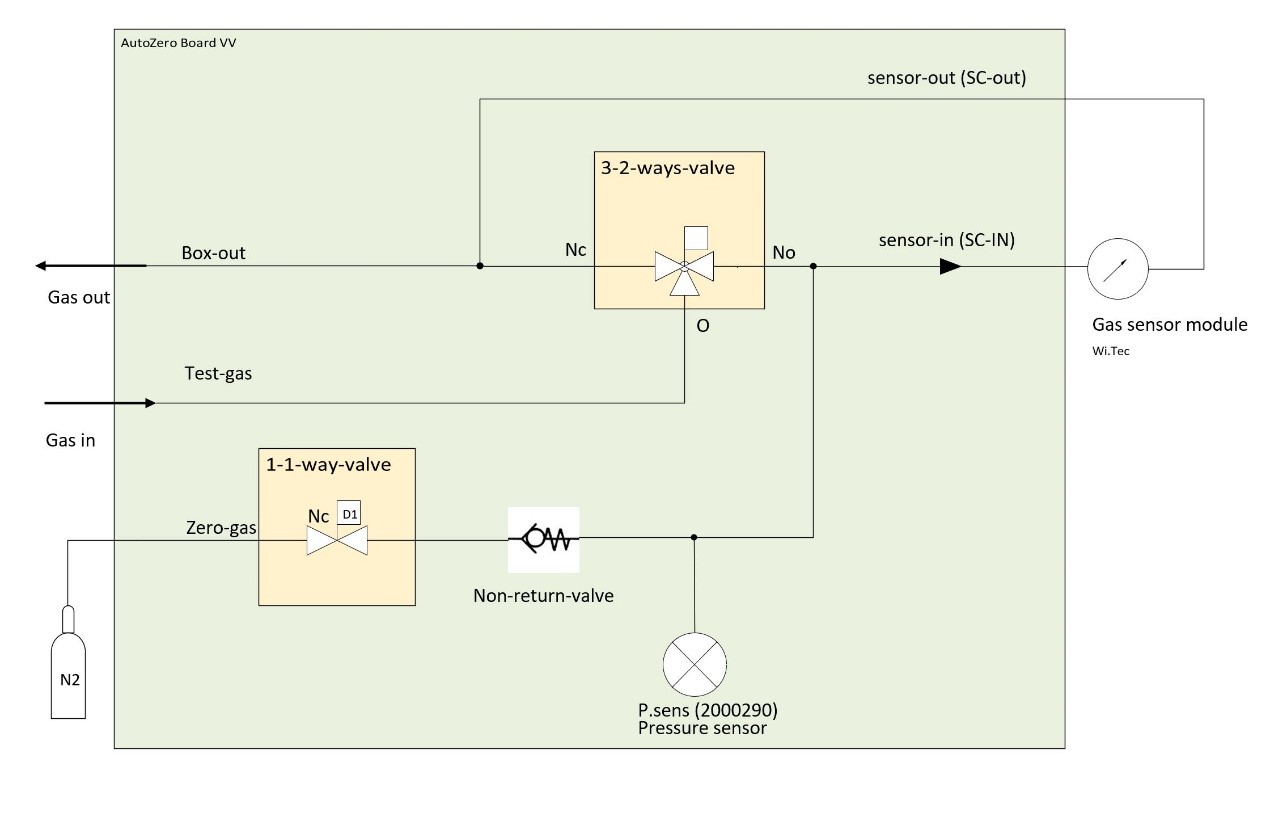

RITTER »MultiGas« Modulo di regolazione del punto zero (N2)

Panoramica

Funzionalità

Specifiche tecniche

Caduta di pressione

Schema del circuito

Uscita di tensione analogica

Panoramica

Dati tecnici

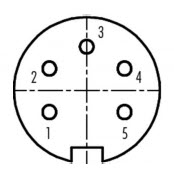

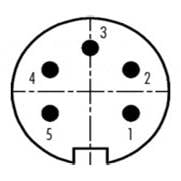

Contatto No. Assegnazione al canale Colori dei fili del cavo di collegamento in dotazione 1 canale 1 bianco 2 canale 2 verde 3 canale 3 giallo 4 canale 4 grigio 5 massa marrone Riscaldamento e termostatazione dell'involucro del sensore

Panoramica

Funzionalità

Filtro

Panoramica

Descrizione

Applicazioni

Funzionalità

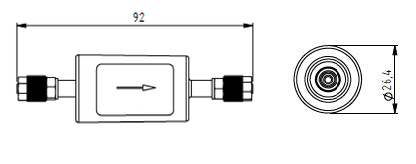

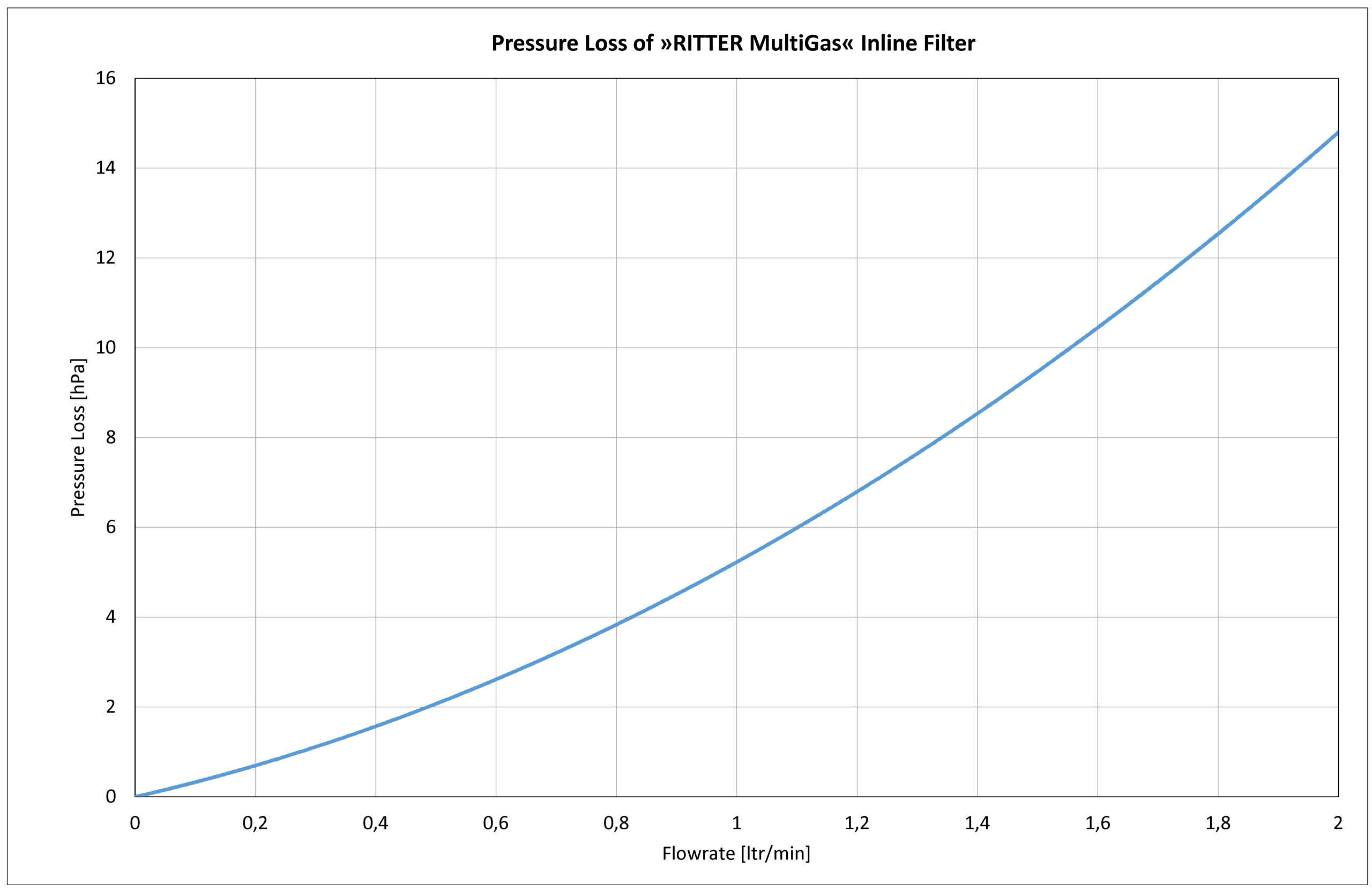

Dimensioni

Specifiche tecniche

Caratteristiche Generali

Dimensioni Ø 26,4 mm x 92 mm Peso 26 g Connettore per tubo 4/6 mm tubo Portata 0 – 4 ltr/min Applicazione Filtro antiparticolato Volume degli alloggi 110 ml Materiali a medio contatto Poliammide (alloggiamento), acciaio inox (connettore), FKM (O-ring) Intervallo di scambio Dipende dalla contaminazione del gas Caduta di pressione (mbar) @ 1 ltr/min < 6 mbar Parametri del gas

Temperatura di esercizio -5 °C – 60 °C Temperatura di stoccaggio -20 °C – 110 °C Pressione massima 8 bar Umidità ambientale 0 – 95% umidità relativa (non condensante)

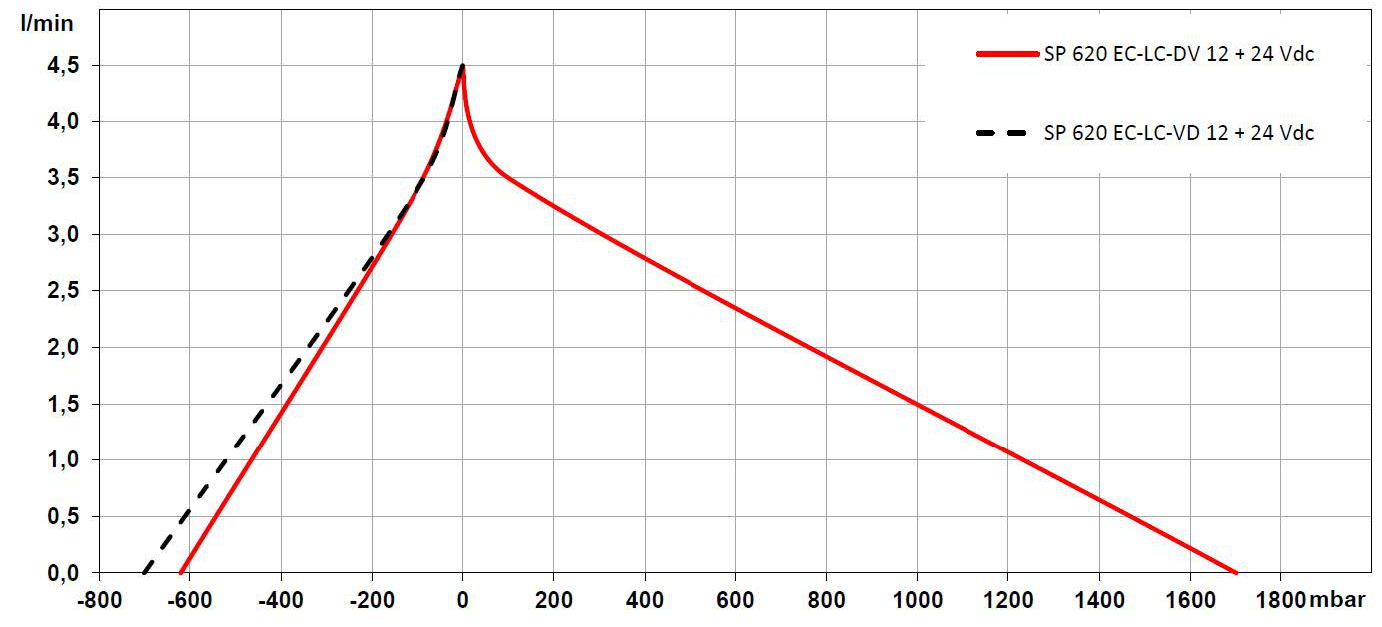

Pompa per il campionamento del gas

Panoramica

Applicazioni

Funzionalità

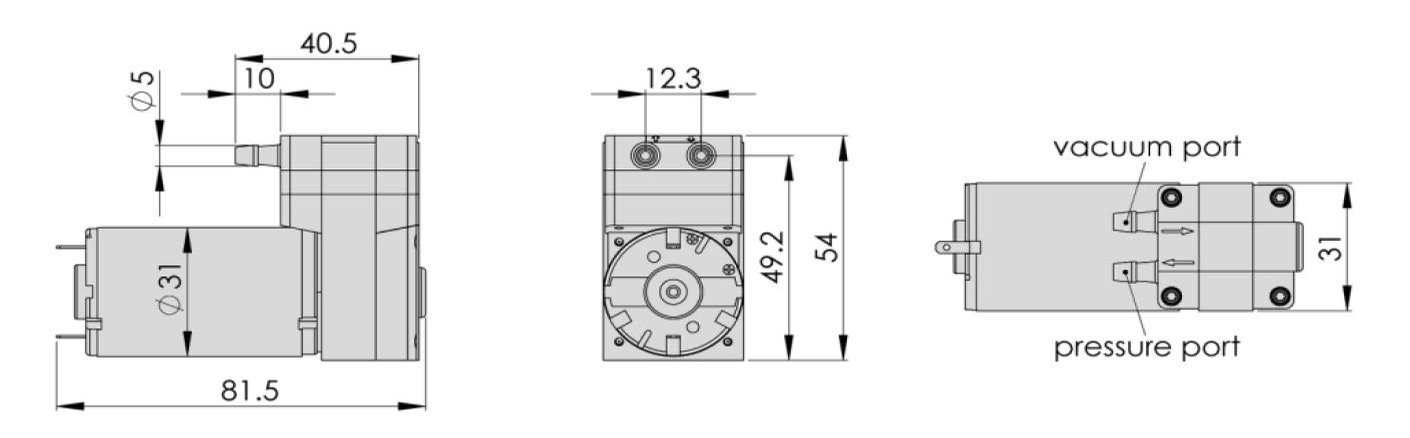

Dimensioni

Specifiche tecniche

Caratteristiche Generali

Tensione di esercizio 24 VDC Corrente nominale massima 330 mA Connettore pneumatico 4/6 mm tubo Portata 0 – 4,5 ltr/min Pressione massima 1,7 bar Vuoto massimo -620 mbar Materiali a medio contatto PVDF (testa della pompa)

PTFE (membrane)

FFKM (valvola e guarnizione)Peso 184 g Dimensioni L x H x L 31 mm x 54 mm x 81,5 mm Parametri del gas

Temperatura di esercizio 5 °C – 50 °C Temperatura di stoccaggio -20 °C – 60 °C Umidità ambientale 0 – 95% umidità relativa (non condensante) Diagramma delle prestazioni