Application

The High-Precision Packing Liquid Level Indicator »HPLI« allows highly precise reading and setting of the packing liquid level in RITTER Drum-type Gas Meters. Precise adherence to the factory-set level is very important for the Meter’s measurement accuracy, as the measurement deviation given in the Calibration Certificate is only valid when the packing liquid level is correct. Packing liquid levels other than that set in the factory cause the volume in the chambers of the measuring drum to be different to the volume at time of calibration, which inevitably results in a measurement error.

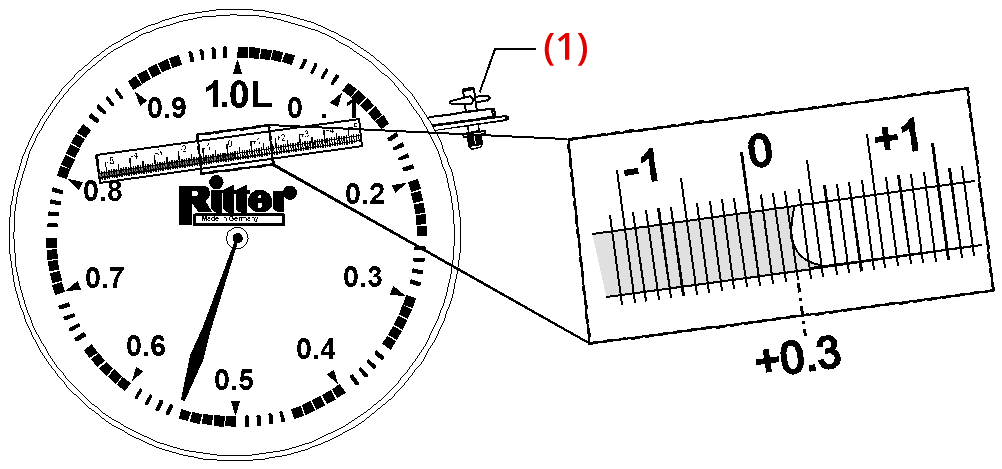

(1) Screw cap (not with high pressure meters; with high pressure meters the upper end of the High-Precision Packing Liquid Level Indicator »HPLI« tube is connected to the inside of meter casing above the liquid level.) Location of indicator shown for models TG 05 to TG 10. Location with models TG 20 to TG 50: Beside of the counter mechanism casing.

Operational principle

The High Precision Packing Liquid Level Indicator »HPLI« consists of the following parts:

Following the principle of communicating pipes, the sloping tube is connected with the packing liquid in the Gas Meter casing. Because of this, the liquid level in the sloping tube exactly reflects the level in the Gas Meter casing. Because the tube is sloping i.e. set at a small angle to horizontal, a small change in the liquid level in the Gas Meter casing results in a large change in the liquid level inside the sloping tube. Thus, the sloping tube acts like a »magnifier« of the liquid level inside the casing and can therefore be set extremely precisely. Furthermore, a parallax error when reading the level, which can occur with the Standard Level Indicator, is nearly impossible.