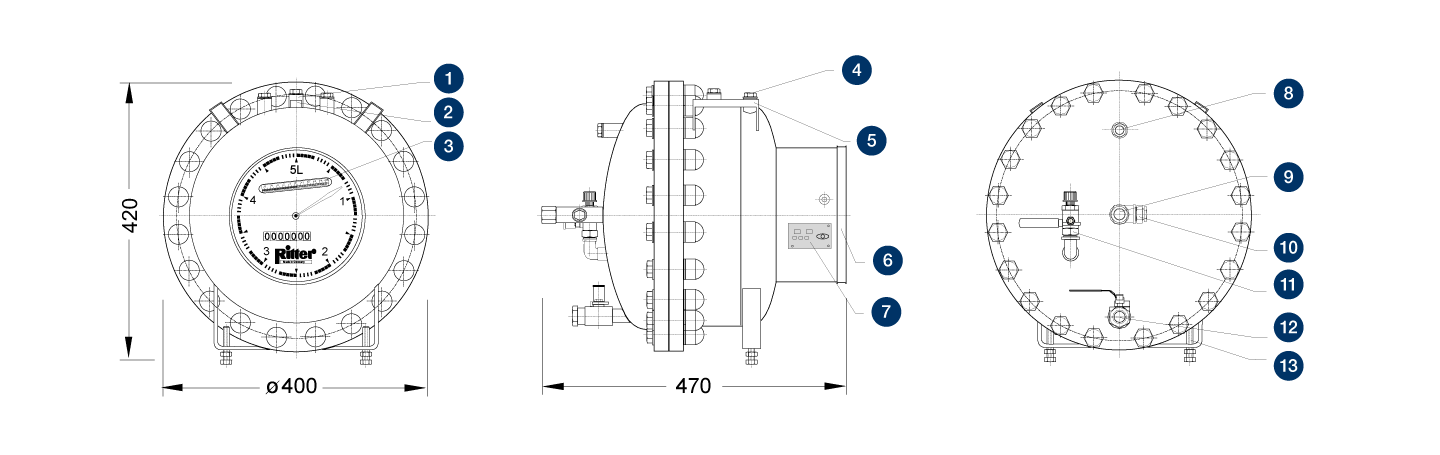

Legend

- Filling nozzle

- Level

- Precision liquid level indicator »HPLI« (option)

- Support unit for:

- Thermometer (gas)

- Thermometer (packing liquid)

- Handle

- Removable cover

- Pulse generator port (option)

- Gas outlet

- Gas inlet

- Manometer connection

- Standard liquid level indicator

- Drainage faucet

- Levelling foot

Performance Data

| Minimum flow Qmin | 10 | ltr/h |

| Standard flow Qstandard | 500 | ltr/h |

| Maximum flow Qmax | 600 | ltr/h |

| Measurement accuracy at standard flow | 0.2 | % |

| Measurement accuracy across measuring range | 0.5 | % |

| Measuring drum volume | 5 | ltr/U |

| Packing liquid quantity, approx | 12 | ltr |

| Maximum gas inlet pressure | 6 | bar |

| Minimum differential pressure (1) | 0.2 | mbar |

| Minimum dial division | 0.02 | ltr |

| Maximum indication value (2) | 99,999,999 | ltr |

| Connection gas in/outlet | hose barb | |

| Inside-Ø hose barb | 10.6 | mm |

| Outside-Ø hose barb | 15 | mm |

(1) Differential pressure (= pressure loss) gas inlet gas outlet

(2) Standard Totalizing Roller Counter

(2) Standard Totalizing Roller Counter

Models (materials)

| Model | Casing | Measuring drum | Width | Height | Depth | Weight (without packing liquid) | Max. constant use temperature |

|---|---|---|---|---|---|---|---|

| 1 | Stainless Steel | PVC-grey | 400 mm | 420 mm | 470 mm | 31.1 kg | 40 °C |

| 2 | Stainless Steel | PE-el | 400 mm | 420 mm | 470 mm | 30.9 kg | 60 °C |

| 3 | Stainless Steel | PP-grey | 400 mm | 420 mm | 470 mm | 30.9 kg | 80 °C |

| 4 | Stainless Steel | PVDF | 400 mm | 420 mm | 470 mm | 31.5 kg | 80 °C |

Caution

Before and after measurements with oxygen purge the meter with an inert gas to avoid the danger of explosion!

For chemical resistance properties please contact your RITTER distribution partner!

Standard Equipment

- Multi-Chamber Measuring Drum

- Magnetic coupling between measuring drum and counter (for an absolutely liquid-tight casing)

- 8 or 9-digit Totalizing Roller Counter

- Large One-needle Dial

- Supports for Thermometer and Manometer

- Viton sealing

- Level and Levelling Feet

- Bubble level for levelling

Built-in Options

- LCD Display, resettable, 8-digit (replaces Totalizing Roller Counter)

- Pulse Generator, standard or Ex-proof version (for connecting Electronic Display Unit/Computer)

Accessories

- Software »RIGAMO« RIGAMO

- Resistance Temperature Sensor (Gas), 100 mm

- Resistance Temperature Sensor (Packing Liquid), 200 mm

- Pressure Transmitter

- Electronic Display Unit »EDU 32 FP«, displays volume and calculates flow rate via RS232 and analog-output in realtime (pulse generator required)

V 1.0 / Rev. 2024-02-07 / Subject to alterations.

The most recent version of this data-sheet can be found at …

https://www.ritter.de/en/tg-5-stainless-steel-6-bar/

Dr.-Ing. RITTER Apparatebau GmbH & Co. KG · Coloniastrasse 19-23 · D-44892 Bochum · Germany

For questions please contact mailbox@ritter.de or your local distribution partner (on our overview page)

https://www.ritter.de/en/tg-5-stainless-steel-6-bar/

Dr.-Ing. RITTER Apparatebau GmbH & Co. KG · Coloniastrasse 19-23 · D-44892 Bochum · Germany

For questions please contact mailbox@ritter.de or your local distribution partner (on our overview page)