Beschreibung

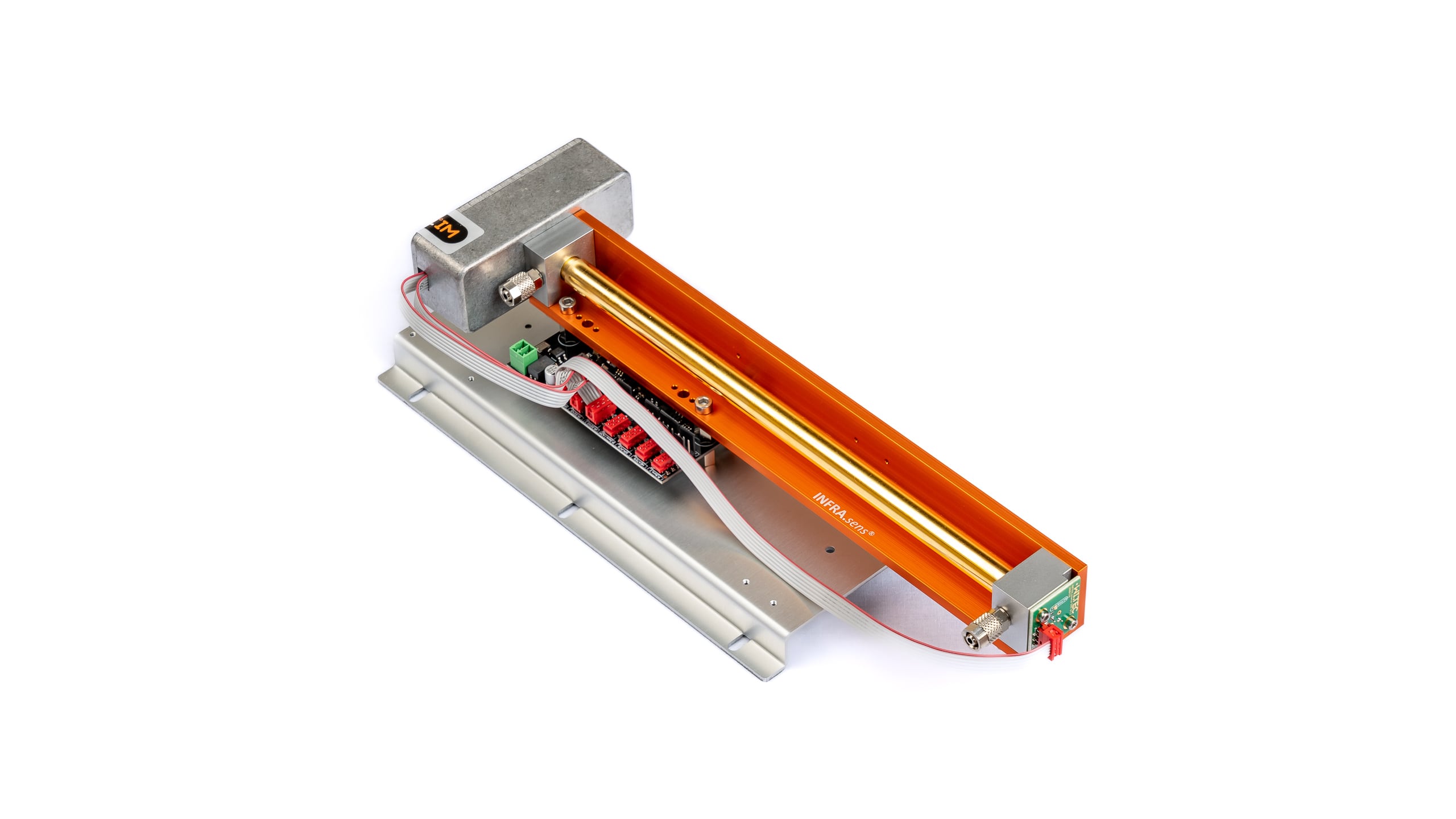

Die Gasanalyse auf Basis der NDIR-Technologie ist eine etablierte Methode, um die Konzentration von Gasen in komplexen Gemischen zu bestimmen. Die RITTER »MultiGas« Sensoren verwenden innovative optische Komponenten für optimale Analyse-Ergebnisse: Bis zu 3 optische Filter analysieren das Gas, welches als Gasstrom durch den Sensor fließt. Die optionalen Sauerstoff-, Druck- und Feuchtesensoren messen dabei denselben Gasstrom. Die einzelnen internen Module sind durch O-Ring-Verbindungen abgedichtet. Um eine optimale Anpassung an den gewünschten Messbereich zu erreichen, können die Längen der modularen Messzellen (= Küvetten) im Bereich von 5 mm (großer Messbereich im Prozentbereich) bis 250 mm (kleiner Messbereich im ppm-Bereich) verbaut werden. Bei Küvettenlängen ≥ 20 mm ist die Innenwand mit einer widerstandsfähigen Goldschicht beschichtet, um die Reflexionseigenschaften für den Nachweis niedriger Konzentrationen zu verbessern und zusätzlichen einen Schutz gegenüber leicht korrosiven Gasen zu gewährleisten. Die mechanischen Innenteile sind aus Aluminium gefertigt, optional ist auch Edelstahl verfügbar. Für Anwendungen mit hohen Ansprüchen an die Reaktionszeit liefert das Messsystem ein stabiles Ergebnis innerhalb von t90 ≈ 3 Sekunden. Die gesamte Einheit kann zur einfachen Wartung und Service demontiert werden.Anwendungen

Spezifikationen

Allgemeine Merkmale

| Messtechnik: | Innovativer NDIR-Sensor (nicht-dispersiver Infrarot-Sensor) |

| Analysierbare Gase: | CO2 CO N2O CnHm CH4 CF4 SF6 H2O |

| Anzahl der gleichzeitig analysierbarer Gase: | max. 3 pro Sensormodul |

| Messbereiche: | Siehe Tabelle der Messbereiche |

| Volumenstrom-Bereich: | 5 ~ 300 ltr/h Für höhere Durchflussraten kann der Sensor im Bypass betrieben werden. |

| Max. Gas-Eingangsdruck: | 300 mbar |

| Druckverlust (ohne optionale Sensoren): | 10 @ 100 / 35 @ 200 / 70 @ 300 (mbar @ ltr/h) |

| Temperaturausgleich: | Ja |

| Software zur Datenerfassung: | Ja |

| Lebensdauer der IR-Strahlungsquelle: | > 40 000 h |

| Messküvette: | Aluminium, bei Messbereichen ≤1% innen vergoldet |

| Küvettendichtung: | Viton O-Ring |

| Gehäuse: | Hochwertiges Tischgehäuse, Aluminium |

| Abmessungen (W x H x L): | 171 x 86 x 290 mm |

| Gewicht: | ca. 2 kg |

| Gasanschlüsse: | PVDF-Schlauchverschraubung für Schlauch Øi 4 mm, Øa 6 mm |

Messdaten

| Linearitätsfehler: | < ± 1% F.S. |

| Wiederholgenauigkeit: | ± 0,5% F.S. |

| Langfrist-Stabilität Nullpunkt: | < ± 2% F.S. / Woche |

| Langfrist-Stabilität Messbereich: | < ± 2% F.S. / Monat |

| Temperatureinfluss auf Nullpunkt: | < 1% F.S. / 10K |

| Temperatureinfluss auf Messbereich: | < 2% F.S. / 10K |

| Querempfindlichkeit: | < 2% F.S. |

| Druckeinfluss: | < 1.5% / 10hPa vom Messwert |

| Aufwärmzeit: | 2 min |

| Ansprechzeit (t90): | ≈ 3 sec |

| Abtastfrequenz durch Software: | ≤ 10 Hz |

| Nachweisgrenze: | Siehe Tabelle der Nachweisgrenzen |

| Auflösung: | 0,5 x Nachweisgrenze |

| Wasserdampf: | Kein Einfluss auf Messungen von CO2 und CH4 |

Elektrische Merkmale

| Stromversorgung: | 24 VDC inkl. Netzstecker 100 ~ 240 VAC 50/60 Hz: 24 VDC |

| Durchschnittliche Leistungsaufnahme: | < 1W |

| Schnittstellen: | USB (Standard), RS232 / CANbus / CANopen (optional) inkl. Datenübertragungskabel 1 m |

| Analoger Spannungsausgang (Option): | 0 – 2 V / 0 – 5 V / 0 – 10 V |

Gas-Parameter

| Betriebstemperatur: | +15 ~ +45 °C |

| Lagertemperatur: | –20 ~ +60 °C |

| Betriebsdruck: | 800 ~ 1200 hPa (mbar) |

| Umgebungsfeuchtigkeit: | 0 ~ 95% rel. Luftfeuchtigkeit Kondensatbildung im Inneren des Sensors muss verhindert werden! |

* Analyse von CnHm: Die Kalibrierung der Sensoren für CnHm wird mit Propan durchgeführt. Aromatische Kohlenwasserstoffe werden ebenfalls gemessen, jedoch mit einer anderen Gewichtung. Dieses bedeutet, dass die Empfindlichkeit des Sensors bei diesen Gasen deutlich geringer ist als bei anderen Kohlenwasserstoffen.

Liste der Standard-Messbereiche *1 ( und Nachweisgrenzen *2 )

| Standard-Messbereiche mit jeweiligen Nachweisgrenzen ( % vom MBEW *3 ) | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 Vol.% | 50 Vol.% | 30 Vol.% | 20 Vol.% | 10 Vol.% | 5 Vol.% | 1 Vol.% | 5.000 ppm | 2.000 ppm | 1.000 ppm | 500 ppm | 300 ppm | 100 ppm | 50 ppm | 10 ppm | 1 ppm | |

| CO2 | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,3%) | (< 0,3%) | ||||

| CO | (< 0,2%) | (< 0,2%) | (< 0,2%) | (< 0,2%) | (< 0,2%) | (< 0,2%) | (< 0,2%) | (< 0,3%) | (< 0,5%) | (< 0,5%) | ||||||

| N2O | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,3%) | ||||||||

| CnHm*4 | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,2%) | (< 0,2%) | (< 0,2%) | (< 0,2%) | (< 0,5%) | (< 0,5%) | |||||||

| CH4 | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,3%) | (< 0,5%) | |||||||

| CF4 | (< 0,2%) | (< 0,2%) | (< 0,2%) | (< 0,02%) | (< 0,05%) | |||||||||||

| SF6 | (< 0,1%) | (< 0,1%) | (< 0,1%) | (< 0,2%) | (< 0,5%) | (< 0,3%) | (< 0,3%) | |||||||||

| H2O | ||||||||||||||||

Infrarot-Modul NDIR Ultraviolett-Modul NDUV

Definition der Nachweisgrenze

Die Nachweisgrenze ist der kleinste Messwert, der mit einer bestimmten Unsicherheit ermittelt werden kann. Diese Unsicherheit beinhaltet die Auflösung, das Rauschen und die Stabilität des Gassensors für ein bestimmtes Gas und einen bestimmten Messbereich. Zur Ermittlung der Nachweisgrenze werden mehrere Einzelmessungen unter identischen Messbedingungen durchgeführt. Mit den erhaltenen Werten der Einzelmessungen wird die Standardabweichung "Sigma" (σ) berechnet. Die in der Tabelle angegebenen Werte entsprechen dem dreifachen Betrag von Sigma.

Rekalibrierung

Für IR-Sensoren werden die folgenden Rekalibrierungs-Intervalle empfohlen:V 1.0 / Rev. 2023-12-12 / Änderungen vorbehalten.

https://www.ritter.de/multigas-ndir-infrarot-module/

Dr.-Ing. RITTER Apparatebau GmbH & Co. KG · Coloniastrasse 19-23 · D-44892 Bochum · Germany

Bei Fragen wenden Sie sich bitte an mailbox@ritter.de oder an Ihren lokalen Vertriebspartner (auf unserer Übersichtsseite)